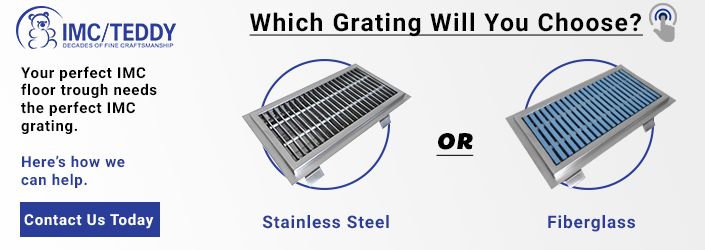

IMC Stainless Steel Grating vs. Fiberglass Grating

IMC Floor troughs are an essential item in any commercial facility & crucial for draining off any liquid on the floor. However, a IMC floor trough is not complete without an IMC grating.

If we talk about the use of grating in a commercial environment, there are two types of common surfaces: stainless steel & fiberglass. Both have their own properties & it is very important to know the differences & advantages of each in order to choose the correct one according to your project specifications.

In this article, we will explore the two types of IMC grating, then pit them against each other to see which one is superior.

About Stainless Steel Grating

Simply put, stainless steel grating is non-corrosive, making it a perfect fit for facilities that are susceptible to toxic environments. Stainless steel grating is also known for its resistance & durability.

Furthermore, stainless steel grating works better in moist/wet environments. If your facility has large wheeled equipment, stainless steel grating works better in the long run.

About Fiberglass Grating

Fiberglass grating is also rustproof as well as slip-resistant & lightweight. It combines corrosion resistance with strength for use in unforgiving environments.

Fiberglass grating can also withstand very heavy loads & can be reinforced through bonding, if necessary. Fiberglass is also nonconductive, making it a good fit for environments with little electricity.

Grating Showdown: Stainless Steel vs. Fiberglass

Stainless Steel has been the common preference in the past but currently, fiberglass gratings have become more viable.

In terms of strength, fiberglass is just as durable as stainless steel. Although fiberglass is rigid, it is just as flexible as stainless steel. This flexibility gives fiberglass endurance & resistance to big impacts.

In terms of cost, stainless steel grating is slightly more expensive compared to fiberglass grating installation.

So, Which One Is Better?

The truth of the matter is, there is no clear cut, definitive winner. The IMC grating you choose will highly depend on your project requirements & parameters. To help make your choice of grating easier, you should ask yourself some questions:

- In which environment is the grating going to be installed?

- What loads & traffic volume will the grating receive & how often?

- What is your expected maintenance costs, if any?

- Is price an issue? What’s your preferred benefit-cost ratio for the overall project?

At IMC/Teddy, we supply both stainless steel & fiberglass gratings. Available in a multitude of widths & lengths, we are proud to work with you to find the best grating to fit your application. Plus, both grating types are also available in ADA compliant versions. Curious to know more? Check out our grating products here.

Having read this I thought it was really informative.

I appreciate you finding the time and energy to put this article together.

I once again find myself spending way too much time both reading and leaving comments.

But so what, it was still worth it!

Do you mind if I quote a couple of your articles as long as I

provide credit and sources back to your webpage?

My blog site is in the very same niche as yours and my visitors would truly benefit from a lot of the information you provide here.

Please let me know if this ok with you. Thank you!

Hi,

Yes, please feel free to quote any of articles. Please remember to cite back to us in your posts. Thank you again for your positive response & support!

Hola! I’ve been reading your blog for some time now and finally got the courage to go ahead and give you a shout out from Huffman Texas! Just wanted to mention keep up the fantastic job!|

Great delivery. Outstanding arguments. Keep up the amazing work.|

Hi there, I read your blogs on a regular basis. Your humoristic style is awesome,

keep it up!