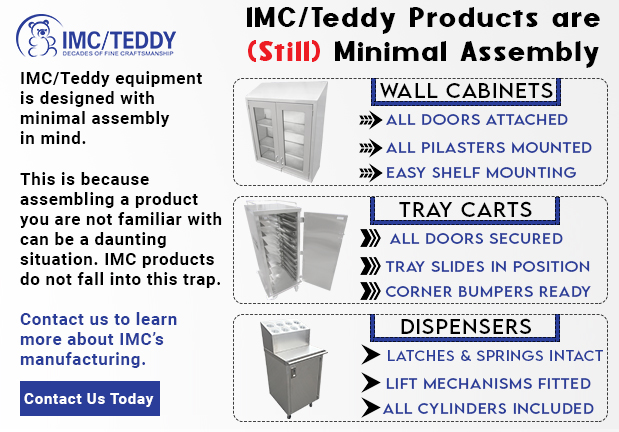

Yes, IMC Products Remain “Minimal Assembly”

One of the most common questions IMC receives about our products is, “Does it come assembled?” It’s an important question that relates to installation & loose pieces, but IMC’s stance remains the same throughout all these years. Most IMC products do not require any assembly at all. For those products that do require it – the assembly is simple & tools are rarely needed.

In this article, we’ll go over common assembly procedures for some the most popular IMC pieces & give you our reason we believe shipping products complete is a decision that benefits you. Let’s start.

Wall Cabinets – Way Too Easy

Wall cabinets ship complete from IMC’s factory. This means all hinged/sliding doors are already on the main body, so you don’t have to fiddle around with getting the doors lined up.

A notable loose piece to pay attention to are the adjustable shelves, which are packed inside of the cabinets themselves (on most occasions). These shelves come with clips which hook onto pilasters within the interior. Once the clips are placed in the matching slots, the shelves can be set up & used – no tools are needed at all! In fact, here’s a quick tutorial video on how to install shelves inside of an IMC wall cabinet. The process only takes few spare minutes.

Tray Carts – Locked & Loaded

Tray carts are a sizable product in our lineup, but they do not have to be assembled on site. All tray carts come with the doors attached, tray slides in position, corner bumpers in place & grab handles mounted. The tray slides themselves can be removed for maintenance, but they snap back into place without the use of tools. We have another short video on removing & inserting tray slides here.

Dispensers – Ready to Roll

Dispensers are mobile storage units that are useful for buffet style operations. There are many components to bear in mind – latches, springs, lift mechanisms, handles, etc. All these pieces are fully integrated into each dispenser & do not have to be assembled on site.

However, depending on your model, the only loose pieces that you need to be aware of are the cylinders that come with each dispenser. These are easily placed inside of the corresponding slots & you’re ready to work.

Stay Together

The above are just a few examples, but why does it matter overall?

Time is of the essence. No one wants to use up precious time in getting equipment to operate. Having equipment that requires minimal installation cuts down on time lost & increases your productivity substantially. Also, having too many loose items shipped with your main equipment can present the problem of misplacement & theft. We’re here to eliminate that issue.

IMC/Teddy understands that your time is important & projects can have tight deadlines. Having as little loose parts as possible is just one way to save you time & focus on other activities. To learn more about how IMC can cater to your stainless steel needs, click here.