It’s Time for a Matchup: Stainless Steel vs. Cast Iron (For Foodservice)

Today’s two commercial kitchen staples are stainless steel & cast iron. Both are classic materials that will continue to be used for years to come. However, there are some key differences between them that can give the slight edge to one material. How do both compare exactly & which metal is ultimately the better choice? We’re here to break it down.

In this article, we'll compare stainless steel & cast iron in foodservice applications. We’ll go over some common uses & the pros/cons of each. Let’s look at the first category.

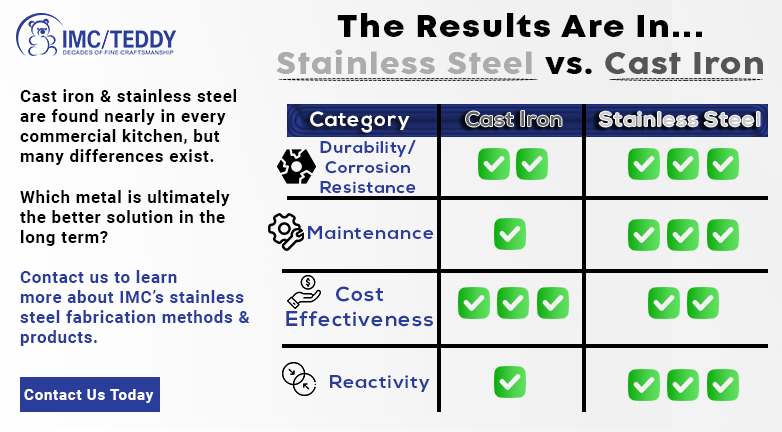

Durability/Corrosion Resistance

Stainless steel is one of the most durable metals to use in the commercial kitchen, but cast iron is no slouch either.

The difference is corrosion resistance – stainless steel is 100% the victor.

Why?

Stainless steel has prominent levels of chromium that acts as a natural barrier against rust. Cast iron needs to be maintained constantly (more on this later) to prevent rust from forming. Furthermore, cast iron should avoid any constant exposure to moisture as this will only speed up corrosion.

Winner: Stainless Steel

Maintenance

Cast iron requires frequent seasoning, meaning you will have to bake thin layers of oil onto the surface, so it hardens. The hardening provides a slick, protective coating that makes the surface non-stick & prevents rust. Stainless steel does not need to be seasoned at all.

Cast iron is NOT dishwasher safe, but stainless steel is perfectly fine in the dishwasher, however. Both materials should be dried afterwards, but cast iron needs to be dried immediately. It should be noted stainless steel can develop water spots if not dried in a timely manner.

As far as other maintenance goes, stainless steel should be polished & cleaned daily to keep that hygienic & shiny surface looking fresh. Cast iron just needs mild soap & warm water.

To sum up, both materials have their obstacles when it comes to maintenance, but stainless steel is much easier to care for overall.

Winner: Stainless Steel

Cost Effectiveness

The budget option is obviously cast iron with its lower upfront costs. Most cast iron equipment is affordable & can be bought in bulk. Stainless steel equipment is at the higher end of the price range due to the cost of raw materials & more intricate manufacturing needed.

Winner: Cast Iron

Reactivity

Reactivity refers to the leaching of metal into food. Cast iron suffers from this greatly but can be avoided if you season the metal properly. In fact, cast iron can make food taste metallic or even turn black if not seasoned correctly.

Stainless steel does not react with foods & will not alter flavors – no matter what the situation is. This is because of the chromium oxide layer making stainless steel an inert metal.

Winner: Stainless Steel

The Winner Is…?

With better durability, rust resistance, easier maintenance & better reactivity, the clear winner is stainless steel. However, cast iron is meant to be used as a budget metal for quick or occasional tasks. Cast iron is also lightweight so it’s easier to wield in a pinch.

Ultimately, the best metal to use will come down to your kitchen needs, but stainless steel just possesses more advantages over traditional cast iron.

Champion: Stainless Steel

IMC/Teddy has been working with stainless steel for almost 70 years, so we know all the ins & outs of what the metal is capable of. Type 304 stainless steel is one of the most used stainless steel alloys in today’s commercial kitchens & our preferred metal of choice. For a closer look at IMC’s products, click here.