Are All Stainless Steels Magnetic?

Magnets. How do they work exactly? It’s the age-old question that has been an invisible force throughout our entire lives. The applications have spanned generations from compasses to refrigerators to speakers. In simplest terms, two opposite poles come together to create an “attraction” & thus forming a magnetic field. How does this apply to stainless steel? More importantly, how does this affect stainless steel in a foodservice environment?

In this article, we’ll give you a simple breakdown of stainless steel magnetism & what this means for foodservice equipment as a whole. Let’s begin.

So, Are All Stainless Steels Magnetic?

In a word, no.

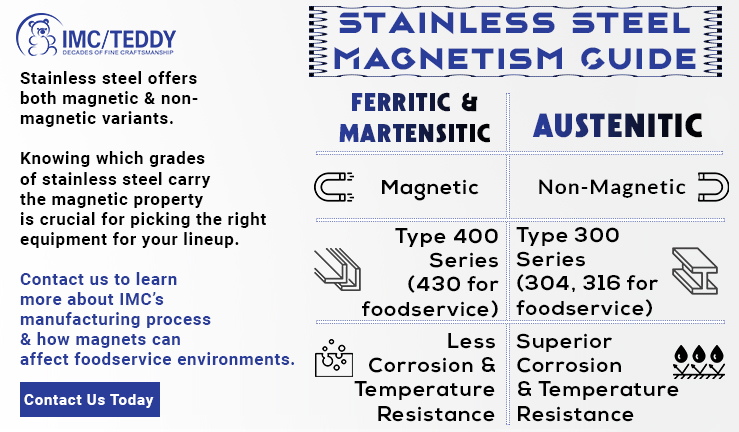

However, there are certain types that absolutely are & you should be aware of them in the foodservice world. First, a breakdown of some terminology:

Ferritic & Martensitic – These types of stainless steels ARE magnetic. They typically encompass the Type 400 series stainless steel grades. Type 430 is a common foodservice grade & is indeed magnetic. This type of grade has less corrosion & temperature resistance; however, it is well suited for mildly acidic environments.

Austenitic – These types of stainless steels ARE NOT magnetic. Type 300 series is a typical example of this. In particular, Type 304 & Type 316 are the main foodservice grades. Type 304 is IMC’s stainless steel of choice thanks to its cost effectiveness & ease of use during manufacturing. Type 316 stainless steel is a relatively more expensive option. 316 is better suited for outdoor environments & larger scale applications such as boilers or processing equipment. Lastly, austenitic stainless steel offers superior corrosion & temperature resistance.

What Does This Mean for the Foodservice Industry?

It’s important to note that magnets themselves do not make food unsafe. No matter what grade you choose, stainless steel is inherently hygienic & easy to clean so magnetic properties do not factor into the overall food safety aspect.

However, other safety concerns may arise. Knives, in particular, can stick to magnetic surfaces creating a sharp edge that can harm employees or patrons. This is the main reason to consider non-magnetic stainless steel for foodservice operations, apart from resistance to corrosion.

Besides dangerous utensils, other metal utensils such as forks or spoons can stick to the stainless steel surfaces creating an inconvenience.

Magnets & metal go hand-in-hand, but stainless steel is one of the few metals that can be non-magnetic & magnetic. In the foodservice world, Type 300 series is a clear winner if you are looking for a material that is more resistant to corrosion while being non-magnetic. To learn more about IMC’s manufacturing process, click here.

Thank you for the Stainless Steel clarification. I have experience with Hood manufactures who use 301 stainless. Is 301 magnetic and as good as 304?

Hi Melvin,

Thank you for your comment. Type 301 is naturally non-magnetic, but can become magnetic through cold forming. Both 301 & 304 are corrosion resistant. However, 301 is much lower on the corrosion resistance scale when compared to 304 (304 has higher nickel & chromium content, which makes it highly resistant to corrosion). This makes 301 less ideal in a kitchen/foodservice environment. Let it be known that 301 is still useful in areas where you’ll see a mild corrosive environment, but kitchens overall can be acidic/volatile so 301 is not the greatest choice to use, in our opinion. Hope this clarifies the difference between the two, please feel free to contact us if you have questions. Thank you again for your interest.

Thank you for the clarification. Some hood manufactures try to push 301 because my specifications call for 304 .