Corner Guards: Your Questions Answered

Corner guards are often a forgotten item in your commercial facility. Today’s construction techniques often leave outside corners of walls exposed due to the low impact resistance of drywall. Do corner guards really help? If so, what is the best type to use & how do you properly take care of them? We’re here to answer those particularly important questions.

In this article, we'll go over 4 of the most asked questions about corner guards & provide you with some buying tips to aid you in your journey. Let's start with the fundamental question.

1. What are Corner Guards Really Used For? How Many Do I Actually Need?

It’s a two-part question because the answers really go together.

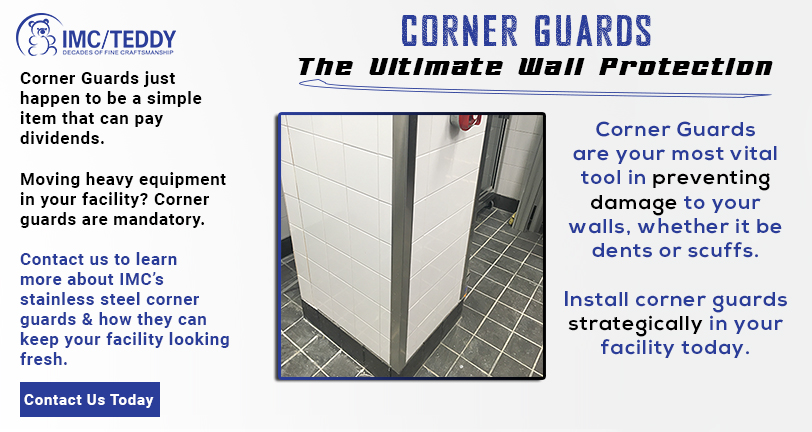

The main function of corner guards is to protect your walls from catastrophic damage & scuffs. For example, wheeled equipment is constantly being transported from one area to another. When you are carrying heavy material down a hallway, there is a tendency to bump corners, especially if the load is so big that it blocks your vision.

At first, you will see scuffs on the corners in the hall, but over time those scuffs will get worse. More specifically, those scuffs will become deep dents, immense scratches, or even missing pieces of your wall. Those missing pieces may also leave a pointy area where someone could get a sleeve caught or, even worse, cut themselves.

Corner guards prevent this wear & tear from taking place & keep employees safe from any injury.

The amount you need will depend on the size of your facility. Strategic placement of corner guards is also key – try to put them in busy areas where equipment will constantly be transported. Key tip: the more the merrier.

Aside from the safety aspect, corner guards add a clean, finished look to corners for aesthetics.

2. What Are They Made Out Of?

Corner guards can be constructed from several materials as per below:

Vinyl – It’s the most common & cost-effective method but does not offer the best protection in the long run.

Rubber – Although provides adequate cushioning (more than vinyl), still does not offer the best long-term protection.

Metal (in particular, stainless steel) – Offers the best protection & better suited for commercial facilities. It’s the best choice for longevity & durability.

3. Are They Permanently Installed?

The answer will depend on the method you use to install your corner guard:

Screw On – It’s the most stable solution, but you’ll have to cover any holes in your wall once the corner guard is removed.

Adhesive – It’s basically a strong glue & it allows better options for placement. However, if removed, it will most likely leave a residue & may even damage your walls.

Double Sided Tape – The easiest solution that requires no tools for placing your corner guards. Once again, it runs the risk of leaving a residue or damaging your walls if removed.

Although corner guard installation is not “permanent” in a traditional sense, it is recommended to not remove them after installation if possible.

4. Any Maintenance Tips?

We’ll address maintenance for stainless steel based corner guards.

The typical rules apply, even for corner guards. Use a soft towel such as a microfiber cleaning cloth when cleaning them. Use a non-harsh cleaning agent as well. Don’t use wool/wire pads or any cleaning products with bleach in it.

Aside from cleaning, corner guards should be checked periodically for any catastrophic damage such as dents or chips. If a corner guard is painted, check for any wear & tear. Always check to see if the corner guard is firmly placed on the wall as well.

Corner guard benefits are obvious – they protect your walls & bring the look of your walls to the next level. This in turn will save you from expensive repairs or maybe even full replacements of your walls. For a closer look at our corner guards, click here.