FAQ: Your (Ice) Cold Food Counter Questions Answered

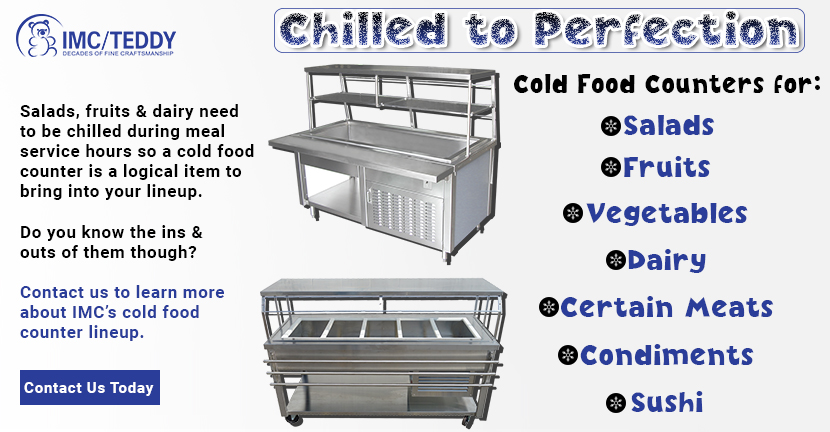

The winter season is here so it would only be appropriate to go over some of your most asked questions about cold food counters. Cold food counters are a meal service staple, mainly found in cafeteria/buffet operations. They are complex items, so naturally many questions are asked about them. IMC is ready to clear the air.

In this article, we’ll go over of the most frequent questions about cold food counters & the best way of integrating them into your current lineup. Let’s begin.

1. How Many Cold Food Counters Do I Really Need?

The answer will come down to a multitude of factors:

a. How big is your operation?

b. What is on your menu?

c. How much space are you allocating?

For larger operations it would be wise to invest in multiple cold food counters to keep your meal service churning.

Certain foods such as salads, fruits or dairy should always be chilled during meal service hours so if your cuisine heavily favors these items, then you’ll need the right amount of cold food counters to accommodate.

Lastly, space is a finite resource & cold food counters can take up a healthy amount of space. Always determine beforehand if your area is ready to take on a cold food counter to avoid any potential delays during meal service.

2. What Kind of Options are Available?

There’s simply too many to name here, but a few popular ones are as follows:

1. Sneeze Guards – used to protect against airborne contaminants & germs that may land on the food,

2. Tray Slides – trays need a temporary rest spot, so tray slides are here to aid you. Can also be configured as a double service style for increased traffic.

3. Display Cases – display your most attractive foods during meal service hours.

The above is just the tip of the iceberg (pun intended). You can find the complete list of options for your cold food counter in our latest price list, pages 146-148.

3. Ice Pan vs. Refrigerated Compartment – What’s the Difference?

It’s a fundamental question, but let us break it down:

Ice pans are non-mechanical & work solely based off melting ice inside of the insulated stainless steel compartment. This means no electricity is needed so setup is a breeze. However, there is less temperature control & the ice & drip pan must be maintained regularly. Ice pans are found on all IMC cold food counter models.

A refrigerated compartment uses a compressor & refrigerant to bring in the chill. This allows for precise temperature control & a better long-term solution. However, certain power requirements are necessary & not all facilities are equipped for this. Refrigeration compartments are found on all IMC cold food counters except Model #CFC, which only has ice pans.

4. Any Cleaning/Maintenance Tips?

We’ve written an in-depth article here, but let’s quickly review the major points.

- Always make sure foods are chilled at 41°F or below. This means checking your refrigeration compartment to see if it is working.

- For ice pans, dump the ice after each meal service & thoroughly clean the interior with water, a mild detergent & a warm cloth. Leave no moisture behind.

- Cold food counters are large, so cleaning might seem like a daunting task, but it must be done. Make sure your cold food counter is spotless & ready for the next meal service.

Cold food counters have many components that should be monitored, keeping a strict maintenance schedule will go a long way.

IMC/Teddy manufactures a variety of cold food counters allowing the ability to add on a delicious dessert, salad or cold food display to your serving line while maintaining them fresh. To see IMC’s complete cold food counter lineup, click here.