Is American Steel Still Competitive in 2025?

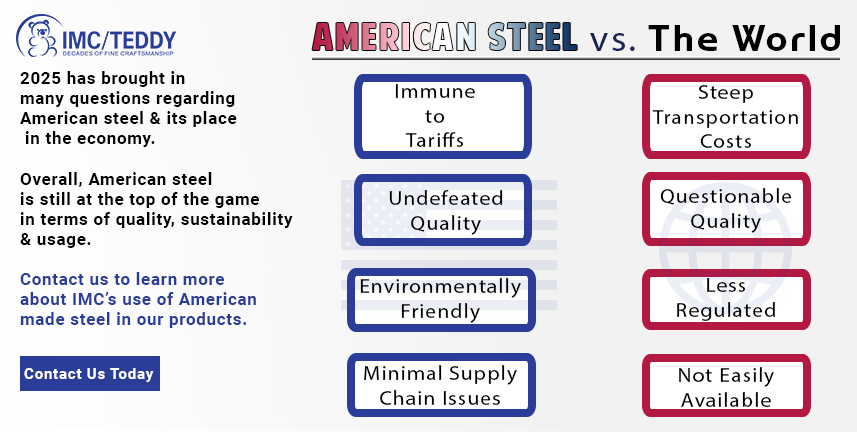

Tariffs have been the talk of the town since the beginning of 2025. With the emerging changes, steel is at the forefront of the discussion as it is the building block for most of the construction in the United States. China, India & Japan are currently the top 3 producers of steel in the world with the USA ranking in at #4. Is American made steel still in the discussion or will it slowly fade away?

In this article, we'll discuss American steel & its currently status right now. We’ll go over the advantages that have taken the front stage in 2025. Let's break down the facts.

Tariffs Need Not Apply

A major advantage of American made stainless steel right now is that it is immune to tariffs. In 2018, a 25% tariff was placed on imported steel from most countries. Earlier this year, this was expanded to more countries & now includes derivative products such as blades or ladders.

Although the effects are unknown as of now, the idea is to increase domestic steel production, wages & jobs. Needless to say, sourcing steel domestically leads to reduced lead times, minimal transportation costs & no supply chain disruptions (more on this one later). Most of all, American steel contributes to over $200 billion for economic output.

Quality is Unbeatable

US steel is at the mercy of some of the strictest quality control standards in the world. Agencies such as ASTM International & American Iron and Steel Institute (AISI) develop & publish technical standards for which steel makers abides by. These standards aim to maintain durability, strength & reliability.

Compare this to another country, such as China, where quality standards are not as strict or robust. The levels of boron & chromium are the key culprit in this. There is no compromise on American made stainless steel.

Yes, American Steel is Environmentally Friendly

Although this may come as a surprise, steel is one of the greenest materials on the planet. It’s fully recyclable & does not produce toxic runoff. This is in part due to the strict environmental regulations that domestic steel plants must adhere to. Steel produced in the United States has less CO2 than competing foreign metals, so that means less greenhouse gases released into the environment.

Supply Chain Issues Averted

American steel offers less chance of supply chain headaches. This is beneficial for projects that need a quick turnaround so lead times are diminished significantly. Also, transportation costs associated with importing foreign steel are eliminated when you procure domestic made steel.

So, American Steel – Competitive or Not?

The short answer, in 2025, is yes – more than ever.

American made steel is undergoing a renaissance of sorts. The continued quality standards, economic impact & easy availability are the key highlights of USA steel at the moment. Although the USA might be #4 on the production scale in the world, USA steel continues to be a gold standard when it comes to delivering a total package for any project.

IMC/Teddy is also a believer in growing the American steel industry & supporting the U.S. economy as a whole. This can only be achieved by investing in American steel & creating a finished product that we can confidently label as 100% USA Made.

IMC manufactures all products using the strongest Type 304 stainless steel in our Amityville, NY factory. Most products are also NSF certified, ensuring the best quality for your facility. To learn more about how IMC can cater to your stainless steel needs, click here.