Let’s Answer Your Questions About Filler Worktables

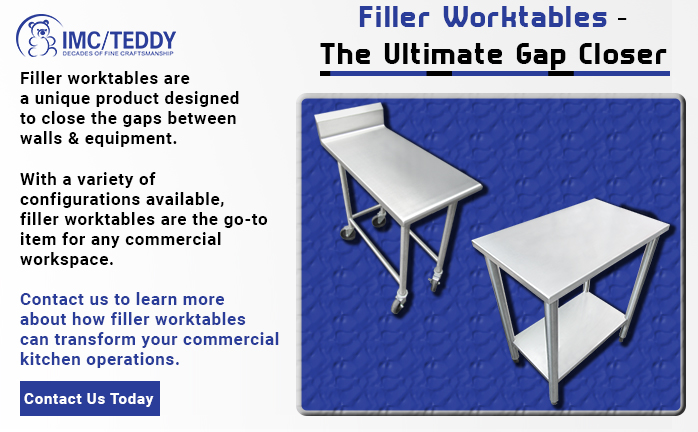

Filler worktables are one of the more unique products in IMC’s catalog. After all, these specially designed worktables have the sole responsibility of “filling” in those awkward gaps that can occur on your commercial floor. IMC Filler worktables not only provide additional prep space, but they also offer further storage locations for smaller equipment. However, not any worktable can instantly become a filler worktable & therein lies the uncertainty.

In this article, we’ll go over 4 questions about IMC’s filler worktables. Let’s start.

1. Do I Really Need a Filler Worktable?

Right off the bat – It’s important to note that filler worktables may not be applicable for your layout.

You may have perfectly calculated & considered all the possible gaps or notches allowing you to fill those dead spaces on the floor. However, there will be times when a shift in layout may cause an unsightly gap to appear between walls or other pieces of equipment. This is where filler worktables come into play.

Aside from just filling in space, a worktable is an essential piece of equipment regardless. They enable you to set up proper prep areas & increase storage (as we mentioned above). Overall, a filler worktable is a handy item if you want to keep your equipment cohesive.

2. So, Why Can’t I Use Any Other Worktable to Fill in the Gaps?

You could, but your spare worktable is probably not narrow enough to fill in the gap in the first place. Filler worktables are no wider than 36” and no longer than 18”. They can even go down to 24” in width and 12” in length.

Obviously, you’ll have to measure the gap itself to determine the appropriate size filler worktable.

3. How Useful is the Storage Really?

With the narrow stature in place, you might think the storage increase will be minimal.

However, filler worktables can be equipped with a fully welded undershelf to expand storage capacity even further. Also, filler worktables can be equipped with casters so they can be easily maneuvered around your facility to other areas that may need extra storage.

The icing on the cake is the available back (8” or 10” high) & side (5” high) splashes so items won’t fall off the table easily, keeping your essentials safe & in place.

If storage isn’t needed that much, crossrails (1-¼” OD) can be equipped instead of an undershelf for extra rigidity.

4. What Can You Say About the Construction/Durability?

You might think durability would be compromised since these worktables are smaller in size. However, that is far from the truth.

All IMC filler worktables are 100% constructed from Type 304 stainless steel with no plastic or galvanized parts. Each worktable comes with reinforcement channels, stainless steel enclosed gussets & adjustable stainless steel bullet feet as well. This automatically makes them one of the most rigid filler worktables on the market as most are made from cheaper steel and/or plastic.

IMC’s filler worktables can also be configured with 14- or 16-gauge stainless steel, depending on the amount of usage (or abuse) you expect to see.

Filler worktables are perfect companions for your worktable lineup & serve a meaningful purpose in your operations. To learn more about how IMC’s filler worktables, click here.