The Truth Behind Sump Sinks (And Why You Need Them)

You may be already familiar with sump pumps (or a sump basin) in your own homes. They are primarily focused on collecting, managing & removing excess water before it can damage your residence. Enter sump sinks. While the function is nearly identical to that of a pump, sump sinks themselves have a specific purpose in the food service industry.

In this article, we will explain the specific uses of sump sinks, compare different materials & detail an IMC product that will aid in your journey. Let’s begin.

What Exactly is a Sump Sink?

When referring to the food service industry, sump sinks (also called a floor drains) are supplementary troughs installed underneath a primary sink. A sump sinks’ job is to filter all of the left over water out of your facility – neatly & quickly. Sump sinks are commonly found underneath compartment sinks, dishtables, worktables with installed sink bowls or any place where drainage may become an issue.

The truth is not all facilities have the proper drainage in the floor to accommodate all of the excess & waste water left over after washing. Sump sinks are here to alleviate that problem.

Excess liquids are commonly filtered from the primary sink to the sump sink by way of a PVC or copper pipe. Sump sinks must be equipped with a strainer to keep all of the large particles & debris from clogging up the drain. A clogged drain can spell disaster & major repairs if left unchecked.

Furthermore, slipping is a real workplace hazard & can be prevented if proper drainage equipment is used. Keep worker safety as priority #1.

Are Most Sump Sinks Made of Stainless Steel?

While we recommend only using stainless steel troughs/drains when dealing with excess liquids, sump sinks can also be made out of simple plastic.

However, plastic is not nearly as durable & does not stand up to the long term abuse. Plastic can eventually crack & warp leading to unreliable drainage. Plastic sump sinks will need to be replaced much quicker than stainless steel equivalents. While initial costs of plastic will be low versus stainless steel, it’s important to look at the long term value.

IMC Model #FDSS – The Ultimate Sump Sink

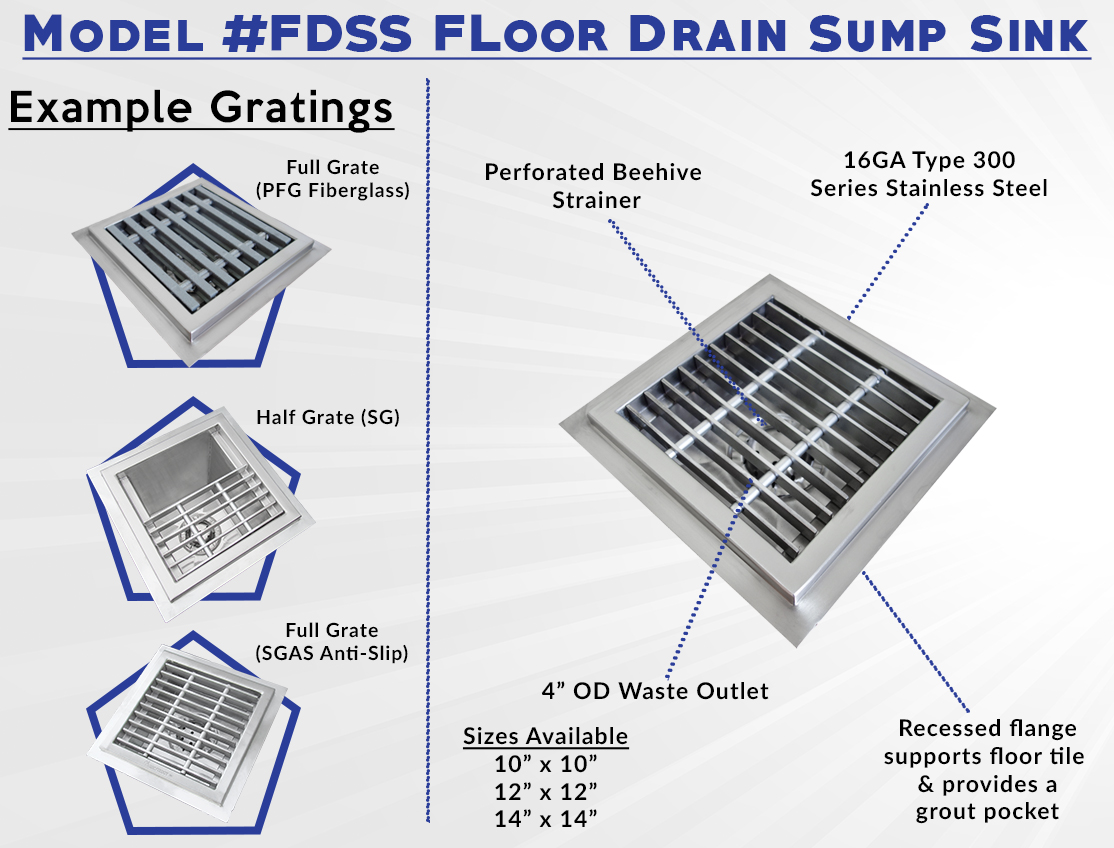

IMC/Teddy offers a signature sump sink, Model #FDSS. FDSS is constructed from 16-gauge type 300 series stainless steel & comes in three square sizes (10″x10″, 12″x12″ & 14″x14″). Standard depth is 4″.

FDSS can be equipped with a variety of stainless steel or fiberglass gratings. A recessed flange & 1″ deep ledge hold the grating in position. Half, ¾, & full size grating is also available based on the kind of pipe you will be using.

FDSS is also 100% NSF certified, so it is safe to use in all commercial environments. Here’s a visual look at Model #FDSS:

IMC knows the importance of having the proper drainage in your commercial facility. A reliable sump sink is mandatory to use in conjunction with a primary sink if floor drainage is inadequate. While cheaper varieties exist, nothing beats the long term reliability & durability of a stainless steel sump sink. To learn more about how IMC’s floor troughs/drains, click here.