The Ultimate Guide to IMC Stainless Steel Floor Troughs Pt. 3 – FWR, NWR, TRE & LFT

Welcome to part 3 of our floor trough series! If you missed part 2 of our series, you can check that out here.

In this part, we will review the newer generation of IMC floor troughs that have gained significant popularity over the past decades. Each of these floor troughs is made in the USA in our factory in Amityville, NY using only type 300 series stainless steel.

Let’s look at Models #FWR, #NWR, #TRE & #LFT.

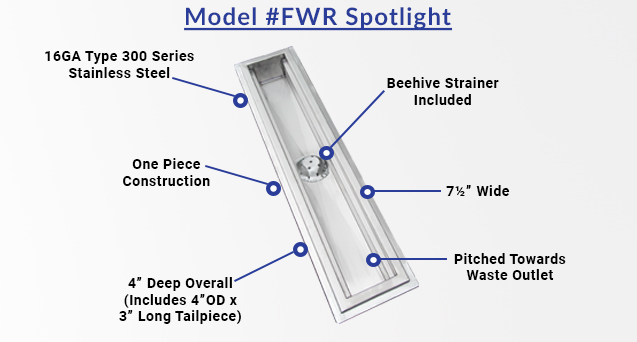

Model #FWR – The Premier Floor Trough for Tight Spaces

Model #FWR is IMC’s floor water receptacle offering. Even in areas with limited space, liquid can begin to accumulate quickly. This is where Model #FWR comes into play. The model is excellent for use underneath ice machines or in front of walk-ins or water discharge areas.

The trough is constructed from 16-gauge type 300 series stainless steel with an overall width of 7½” & an overall depth of 4″.

The trough comes with a modified beehive strainer as a standard & can accommodate up to a 4″ waste outlet. A 3″ long tailpiece is welded to the drain.

Here’s a closer look at Model #FWR:

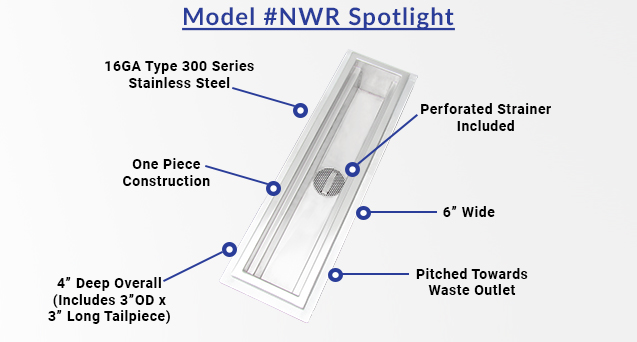

Model #NWR – The Ultimate Floor Trough for Tight Spaces

Model #NWR takes it to the next level & offers an even thinner profile when compared to Model #FWR. Model #NWR offers a staggering 6″ width, which is suitable for those cramped areas with large water discharge.

The trough is constructed from 16-gauge type 300 series stainless steel with an overall width of 6″ & an overall depth of 4″.

The trough comes with a perforated strainer as a standard & can accommodate up to a 3″ waste outlet. A 3″ long tailpiece is welded to the drain.

Here’s a look:

Model #TRE – For Volume Drainage Systems

Model #TRE is ideal for areas where heavy vehicular or light foot traffic is present. Model #TRE is also useful as a perimeter drain & can be interconnected with other floor troughs. It is also useful individually to drain excess liquids.

Model #TRE is constructed from 14-gauge type 300 series stainless steel with an overall depth of 4″. The trough itself is 4″ wide & the length starts at 2′.

For drainage, the trough features a 2″ diameter drain with a standard perforated strainer located at one end as needed. The waste outlet is 2″ OD with 3″ long tailpiece.

Here’s a look:

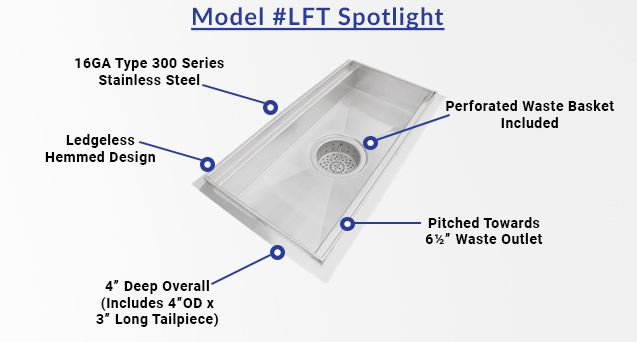

Model #LFT – The Ultimate Slip Resistant Floor Trough

Model #LFT is IMC’s ledgeless design trough. Most troughs in the industry are made with 1½” or 2” ledge, which can get greasy and oily in front of the kettle and cooking area. The ledgeless design eliminates any grease & oil buildup, making the trough virtually slip proof. In fact, this unique design allows for 18% more drainage area.

The trough itself is made from 16-gauge type 300 series stainless steel with an overall depth of 4″.

The trough comes with a perforated waste basket as a standard & can accommodate up to a 4″ waste outlet. A 3″ long tailpiece is welded to the drain.

Here’s a full breakdown below:

The above 4 floor troughs are IMC’s next generation floor troughs. It should be noted that all the above floor troughs may be modified with options to best fit your application. Please check the price book or specific trough spec sheets for a list of options.

Check back for the final Part 4 where we will review IMC’s specialty floor troughs – #IDFD, #FDSS, #FMT & #FTC. For a closer look at IMC’s floor troughs, click here.

This is valuable information. Good to know.

Extremely useful for Foodservice consultants.

Thanks