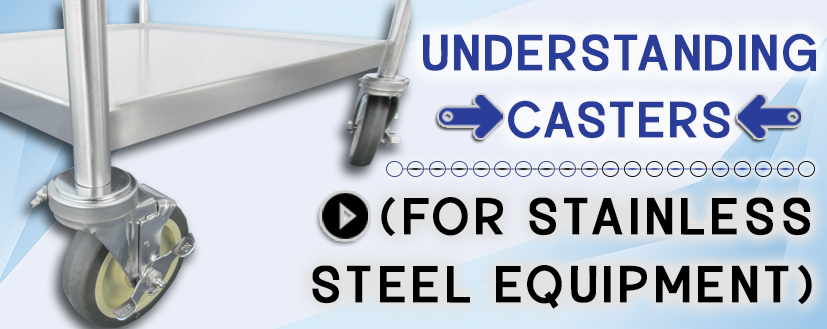

Understanding Casters (For Stainless Steel Equipment)

Today’s commercial facility is a busy, endless flow. Mobility is the name of the game. However, mobility is not possible without the use of casters. In fact, casters make up a staggering $6.5 billion market size in the US & it will only continue to grow. With casters here to stay, why are they a critical component for stainless steel equipment & why should you consider them for your next project?

In this article, we’ll give 4 reasons why casters play a pivotal role in increasing your efficiency & workflow. We’ll also give you a quick breakdown of IMC products where casters are available. Let’s roll on.

1. Maneuverability (of course!)

The most obvious reason for equipping casters to your stainless steel equipment is to unlock mobility.

Let’s face it. Most commercial facilities are crowded & space can be tight. Casters enable you to move around tiny areas & obstacles with ease. Many times equipment needs to be used in different areas of the facility & casters will make transportation a breeze.

2. Extra Load Capacity

The chances are high that your stainless steel equipment is handling very heavy loads at any given time. Casters are durable enough to handle the extra load when being transported. This is useful in high volume facilities where multiple trips are necessary. In fact, many casters can withstand up to 400lbs of capacity.

3. Safety Needs

Although it is something we often take for granted, safety in the commercial facility is paramount. How do casters help to increase safety? Believe it or not, casters are designed to resist the impact of heavy loads & rough surfaces, which diminishes the risk of equipment failing & potential injury.

4. Casters are Actually User Friendly

Stainless steel equipment can be hundreds of pounds. Handling these items can cause a serious strain on the body, especially back pain. Casters allow equipment to move smoothly & effortlessly, reducing physical strain on employees.

IMC Equipment & Casters

Now that you are a pro on casters, let’s look at some IMC products where casters are available. First, IMC 5″ casters always come in a set of 4, where 2 of them have an integrated brake. Swivel casters are standard, but stationary casters can be equipped on request.

As there are too many model #’s to individually name, we will give you a general overview of which product categories are caster ready:

- All IMC Shelving, including all solid & louvered models. The casters themselves add 5″ to the over height of the shelving units.

- Undercounter & Soak Sinks

- Worktables, more specifically mixer/slicer tables, equipment stands, angle frame scale stands, mobile bowl stands & serving tables.

- Storage, Base & Corner Cabinets

- Utility & Transport Carts, which includes dispensers plus any ice & glass storage product.

- Enclosed Tray Carts

- All Modular Serving Systems

Casters are more than simple accessories. They unlock a higher degree of effectiveness for your business not possible before. On a side note, IMC installs the casters on each piece of equipment during the manufacturing process, so you do not have to it yourself in the field. To learn more about how IMC can cater to your stainless steel needs, click here.