Commonly Asked Questions About Floor Troughs

Earlier this year, we went into great detail about the 12 floor trough models currently in our catalog. We hope that video series proved informative, but there may be some lingering questions you have when selecting the best floor trough for your project. We’re here to shine some light on the most common questions regarding stainless steel floor troughs.

In this article, we’ll answer the 5 most common questions concerning floor troughs. We’ll also give you some other helpful resources on floor troughs to aid you in your journey. Let’s start.

1. How about the depth? How do I know what to pick?

The depth of your floor trough will be determined by the liquid flow that you expect. Once again, here’s a general guide to determine the best floor trough depths for you:

2″ – minimal/light liquid flowing into the trough

4″ – moderate liquid flowing into the trough

6″ – gushing/heavy liquid flowing into the trough

Be mindful of the type of environment that your floor trough will be installed. If it will be installed in a remote area with minimal traffic, a 2″or 4″ depth should suffice. However, if you install your floor trough under a sink or a piece of equipment that will have excess spillage, a 6″ depth may be your best bet.

2. What about the grating? Is there a specific one to use?

We know there are a wide variety of gratings available & each have their own properties. The most common type is standard stainless steel subway grating (Model #SG). Anti-slip (Model #SGAS), anti-splash (Model #SG-ATS) & ADA compliant (SG-ADA) versions of this are also available.

If you are looking for a fully enclosed grid style grating that is anti-slip, Model #SQ will be perfect for you.

Pultruded fiberglass alternatives also exist, which is a suitable substitute for stainless steel. Model #PFG is a problem solving material that is structurally strong, anti-slip & corrosion resistant.

Other special types exist such as louvered (Model #LG) & chemgrate (Model #CH). These are used for specific applications.

A word on ADA compliant gratings – they are available for stainless steel & pultruded fiberglass gratings. The difference is the spacing between the bars of the grating is minimized so vehicles, such as wheelchairs, carts, etc. can pass over it safely.

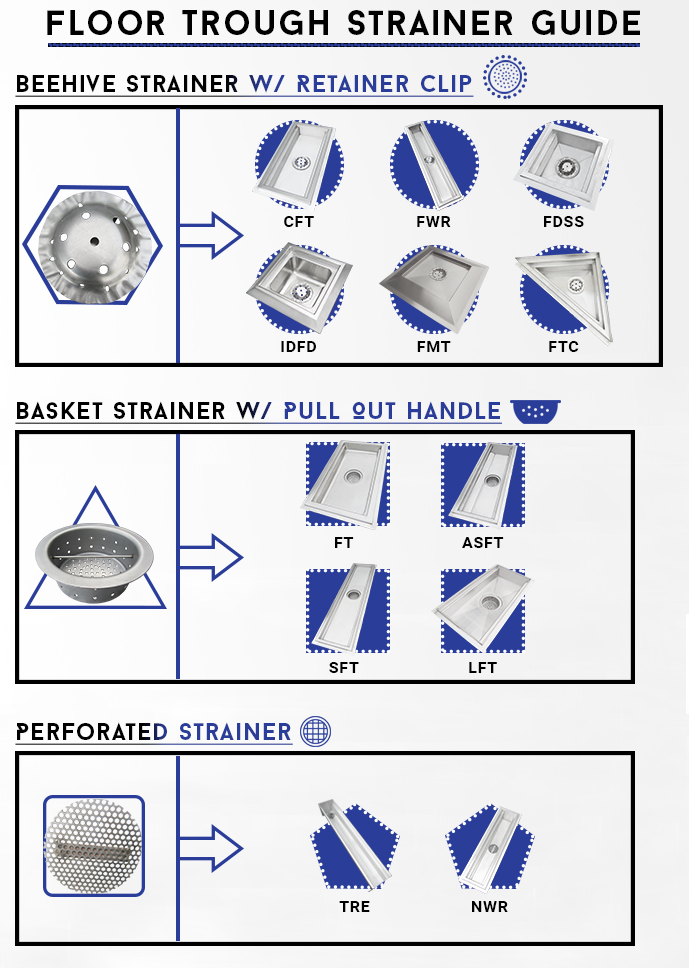

3. What kind of strainer should the floor troughs have?

All floor troughs sold at IMC/Teddy come with the strainer in the trough. That means you will not have to worry about supplying your own strainer. Each strainer is designed to filter out the max amount of debris. As reference, here’s a quick guide to our floor trough strainers for your information:

4. What if I’m installing the trough in a high security area like a correctional facility? What options should I use?

If you are installing floor troughs in a correctional facility, you’ll need to add a Security Package to your floor trough.

A security package means the trough has an extra ledge to lock the grating in place so it’s very secure. This ensures that no part of the trough or grating can be broken off, stolen or used as a weapon. For more info on security troughs, click here.

If you want to add an extra bit of durability to your trough, consider a gauge change (Option model #GA-14) for your floor trough as well. IMC security floor troughs are not available in 12-gauge stainless steel.

5. What if I’m installing the trough on the 2nd or 3rd floor where there is risk of leaks to the below floors?

If you’re installing your floor trough on the upper levels of a building, it’s highly recommended that you equip your floor trough with a Seepage Flange.

A seepage flange (See Option Model #FSG) is integrated into the floor trough & is used to prevent any liquid seepage through the floor, tile, grout or cracks. Instead, the water seeps down to a waterproof membrane & guided into the trough, through the 1/8” weep holes & down the trough drain. This prevents water from going to the area below the floor.

Check out a helpful guide on seepage flange here.

Floor troughs are IMC/Teddy’s flagship product. IMC manufactures floor troughs using the strongest type 304 stainless steel in our Amityville, NY factory. Most IMC floor troughs are also NSF certified, ensuring the best quality for your facility. To learn more about how IMC’s floor troughs, click here.

Please subscribe me to your mailing list. Thank you

Hi Megan,

Thank you for your interest and I’ve added you to our mailing list.

“Your blog always offers such valuable insights. Keep up the fantastic work!