Starting a Ventless Kitchen? Here are the Stainless Steel Essentials

Not all commercial kitchens are the same. Many factors such as aesthetic & space are the reason why no two kitchens are alike. There is one specific type of commercial kitchen that exists that is one of the most unique – ventless. What makes this type so special? More importantly, what stainless steel products fit into this archetype?

In this article, we’ll go over what constitutes a ventless kitchen & go over 4 types of stainless steel products that fit perfectly in the setup. Let’s jump right into it.

Ventless Kitchens – What are they?

If you look at a typical commercial kitchen, there are several hoods positioned around equipment such as fryers or griddles to channel fumes, smoke, & odors out of the work area. Most of the time, these hoods are required by local codes to be present in order to keep safety guidelines in check.

Ventless kitchens are those that lack these overhanging hoods. Instead, fully enclosed equipment is used & debris does not escape into the kitchen area. All scraps & fumes are managed inside the equipment itself using a trap or some kind of filter. With that said, ventless cooking equipment is relatively smaller in size & can be portable. Ventless cooking is an attractive option for seasonal locations or smaller kitchens where space is extremely limited.

Where Does Stainless Steel Equipment Fit?

With the need for compact & capable equipment, you’ll need to complement your items with stainless steel foodservice equipment. Here are the 4 products to keep in mind:

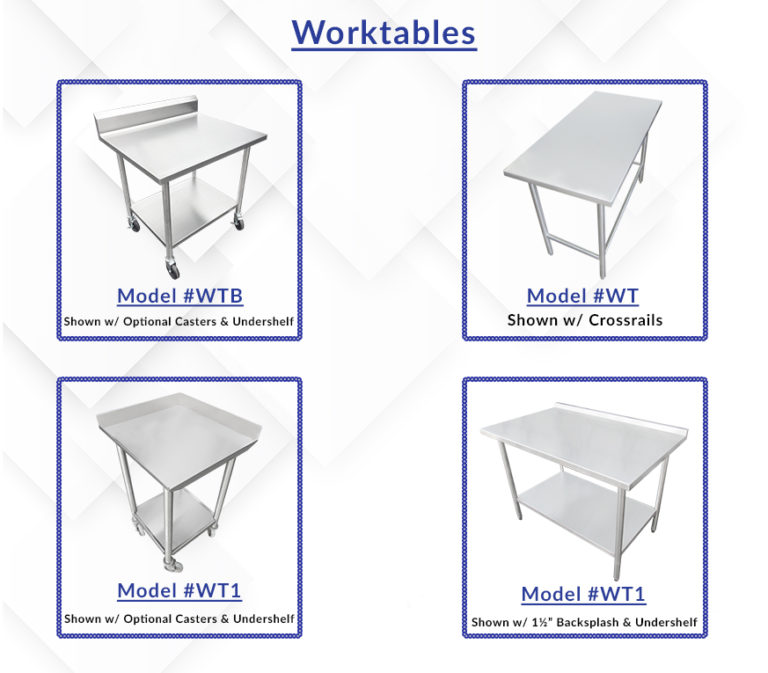

a. Worktables

Ventless deep fryers, ovens & combi ovens are the heart & soul of every ventless kitchen layout. With that said, you’ll want to sit this equipment on top of a reliable surface that is at operating height. This is where worktables come into place. Based on the size of your area, you may need to utilize several worktables to get the job done.

Worktables are also useful when optioned with drawers, undershelves, sink bowls, etc. to save space & eliminate the need for extra equipment.

b. Cabinets

In a ventless environment, small tools & accessories are still needed. This means they will have to be stored in a safe, secure spot when not in use. Cabinets play the role perfectly.

To save the most floor space, consider wall cabinets. If space is plentiful, consider an upright storage cabinet for the largest capacity. Base cabinets can also prove useful as both storage & work space combo. Whatever combination you choose, cabinets are a necessary item in any ventless kitchen.

c. Slicer/Mixer Tables

Although most mixers & slicers do not give off any troublesome smoke or odor, they are still needed in the kitchen to perform tasks. Specially designed mixer & slicer stands are lower in height so equipment can be used comfortably. They are also equipped with casters so you can maneuver your items around the facility with ease.

In fact, any smaller sized ventless equipment (such as rapid cook ovens) can easily be put atop a slicer/mixer table if you want to get the most mobility out of your machines.

d. Equipment Stands

Designed for heavy duty equipment, equipment stands are the workhorse of your ventless kitchen environment thanks to lower gauge construction & reinforced channeling.

Equipment stands also have anti-slip/spill edges so equipment will not slide off the stand. Equipment stands are also lower in height like slicer/mixer tables for operating your machines at a suitable height.

With the rise in ventless (& electric) kitchens across America, the future is indeed bright. With the right lineup of ventless technology & complementary stainless steel equipment, this is the perfect recipe for success. To learn more about how IMC can cater to your stainless steel needs, click here.