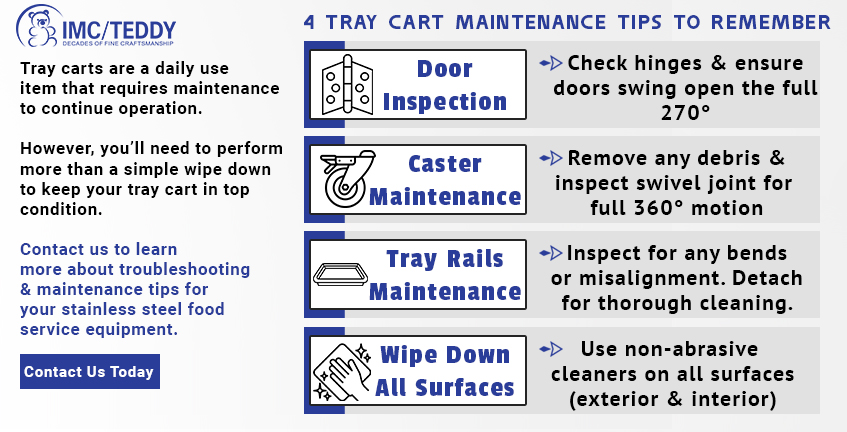

How to Properly Maintain an IMC Tray Cart

Tray carts are meal delivery systems on wheels, which mean they are in constant use. As we all know, more use means more wear & tear. Tray carts are no different. However, they require more than just a simple wipe down as far as maintenance goes. You’ll need to pay closer attention to the details. What should you look out for?

In this article, we will go over 4 ways to properly maintain your IMC tray cart- inside & out. Let’s begin.

1. Door Inspection

Enclosed tray carts operate on the principle of keeping trays secure & stable during use. This is not possible without doors. In fact, doors are probably the most important feature of your tray cart so careful maintenance of them is a must.

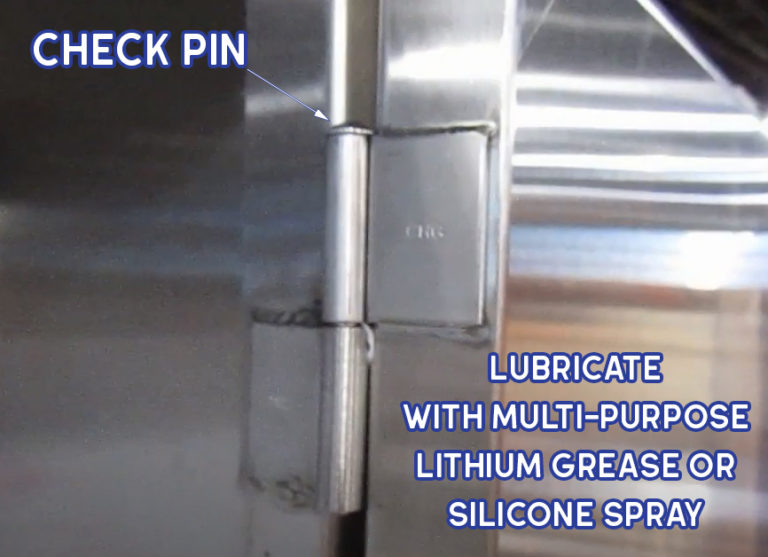

The first thing to notice is odd “popping” noises when opening or closing your door(s). This means it’s time to lubricate the hinges. Multi-purpose lithium grease or silicone spray is the answer. If the door is hitching or you notice any signs of rough travel, check the pin in the hinge for any damage. Here’s some visual help:

2. Caster Maintenance

Casters are needed in order for the cart to maneuver around your facility so keeping them in proper order is a must. Casters must have a smooth travel 100% of the time so inspect the swivel joint for a full 360° range of motion & lubricate the casters. Also, dislodge any visible debris such as dirt with canned air or some high pressure water. Test the brakes regularly as well.

Lastly, check for any balancing issues as well. Each caster should be even with the ground & all should be at the same height.

3. Tray Rails Maintenance

Trays will sit atop your tray rails at all times, so they will need constant care. Check each rail for any bends or misalignment. Each rail should balance a tray perfectly flat without any unevenness. Luckily, the tray rails are detachable so you can perform a thorough cleaning. In fact, they can be removed without tools. Here is the procedure:

a. Lift up rack assembly from the bottom & off of rack pins on the sides of the tray cart.

b. Angle rack to slide off the upper pins.

c. To reinstall, reverse the procedure, starting with attaching the uprights to the pins at the top of the cabinet. Lift up rack and the rack in to fit over the bottom pins.

5. Wipe Down All Surfaces (As Always)

Tray carts can be large, but cleaning every surface is essential. This means addressing the front, back, sides, doors & the interior.

Use a chlorine-free detergent & water. Avoid any bleach or degreasers that contain chlorides or phosphates as these will permanently damage the stainless steel surface. Also avoid using wool pads or wire brushes as these can break off and embed themselves into the stainless steel causing a potential rust issue. Opt for soft microfiber towels or plastic scouring pads with non-abrasive cleaners such as baking soda & a hint of vinegar.

IMC/Teddy manufactures an array of tray carts to accommodate your serving needs. Each one is manufactured from Type 304 stainless steel & made in the USA. Every tray cart is created with 270° swing doors for easy service & washing. Every tray cart features a convenient side load operation, allowing (2) trays per slide on 5” spacing. For our full enclosed tray cart lineup, click here.