Metal Matchup: Stainless Steel vs. Copper (For Foodservice)

The foodservice industry relies heavily on metal. Just look at any modern commercial kitchen, you will find metal equipment & appliances everywhere. Among these metals is most likely aluminum, titanium, iron, copper & stainless steel. Copper & stainless steel in the foodservice environment is interesting, but are they at odds with each other? Well, yes & no.

In this article, we'll compare & contrast stainless steel & copper in foodservice applications. We’ll go over some common uses & the pros/cons of each. Let the matchup begin.

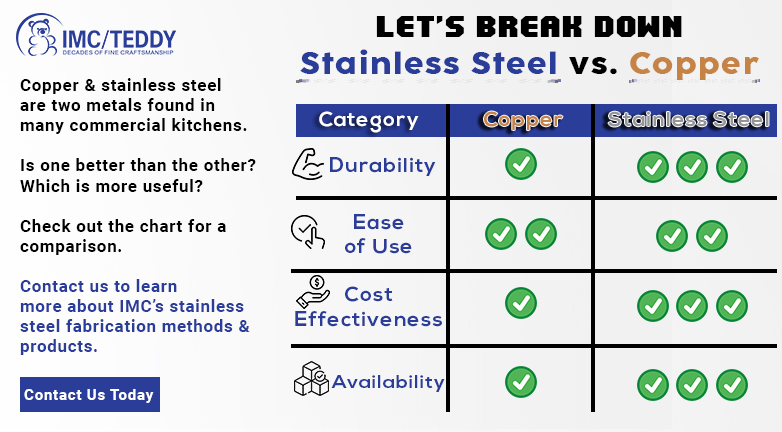

Durability/Corrosion Resistance

This is a clear winner for stainless steel for the following reasons:

- Copper is softer by nature & more prone to scratches.

- Stainless steel is resistant to warping, which is key in highly volatile environments.

- Copper is not corrosion resistant & can in fact develop a “patina” – which is a layer of oxidation that can look like wear.

- Stainless steel maintenance is minimal & cleaning it is a snap. On the flipside, copper requires constant polishing & restoration to keep looking fresh.

However, dents in copper can be easily worked out & repaired while stainless steel dents can be much more of a challenge.

Overall, stainless steel is preferable thanks to its inherent strength & resistance to corrosion.

Winner: Stainless Steel

Ease of Use

This is a mixed bag. Stainless steel is non-reactive so it will not affect the color & taste of the food. However, copper will certainly change the color & taste of the food depending on what it is paired with.

Copper conducts heat way more efficiently with even heat distribution and a faster response to temperature changes making it an ideal choice for specialized kitchens that require precise heat control.

Overall, it will come down to the applications so this will be deemed a draw.

Winner: Tie

Cost Effectiveness

It may be a surprise that copper is actually more expensive than stainless because it is rarer & requires more effort to refine. Copper also requires more labor to prepare & make ready for consumption. In comparison, stainless steel is more affordable & provides better value.

For budget-minded, stainless steel products will fit right in the range you are expecting in terms of affordability.

Winner: Stainless Steel

Availability

As stated above, copper is rare, so it is not as commonly available as stainless steel. Copper is considered niche, so it is not as widely adopted into everyday commercial kitchens. Stainless steel is available as pipes, rolls, sheets, etc. so it’s more accessible.

If you want a specific shape or size of copper, the lead time may also be extended due to the complex manufacturing methods involved. Stainless steel, in comparison, can be shaped easily without much of a lead time increase.

Winner: Stainless Steel

Who is the Champion?

In the world of foodservice, stainless steel is still the king. Copper has its uses & is found in more upscale, high-end commercial kitchens. However, stainless steel is a universal metal in that it can be useful for nearly all applications.

Bottom line: stainless steel that will provide you with the biggest benefits in the short & long term & is the ultimate champion.

Champion: Stainless Steel

IMC/Teddy has been working with stainless steel for almost 70 years, so we know all the ins & outs of what the metal is capable of. Type 304 stainless steel is one of the most used stainless steel alloys in today’s commercial kitchens & our preferred metal of choice. For a closer look at IMC’s products, click here.