Metal Mayhem: Stainless Steel vs. Titanium (For Foodservice)

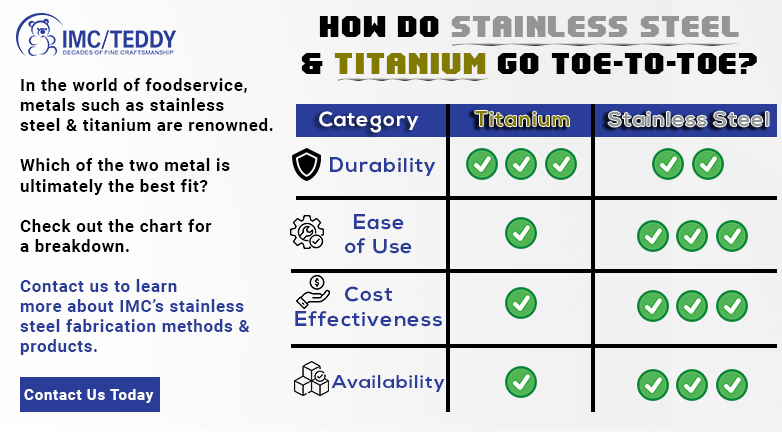

In the realm of foodservice equipment, many metals are utilized daily. Copper, aluminum, iron, stainless steel & titanium are just a few. Of these metals, stainless steel & titanium are odds with each other – & both have their pros & cons. What is the difference between both & which one is better for food service applications? We’ll break down the tale of the tape.

In this article, we'll compare & contrast stainless steel & titanium in foodservice applications. We’ll also give you some insight into the special uses for both metals. Let the games begin.

Durability

Durability is a key feature to boast in the foodservice world. After all, no one wants to deal with broken down equipment (which includes rust) & replacements. Stainless steel is quite durable by itself, but titanium beats it out by a narrow margin.

Titanium simply endures more stress & is inherently “harder” when compared to stainless steel. Titanium also has slightly better corrosion resistance, so it is able to withstand even the harshest environments. Titanium also heats up quickly without deforming, so it is better for applications where rapid heating occurs.

Winner: Titanium

Ease of Use

Stainless steel can be cut, welded, and fabricated even by human hands. The sky is the limit when it comes to what equipment can be born from this metal.

Titanium, on the other hand, requires special machinery during fabrication & is better suited in creating large industrial machinery such as ovens or stoves.

In the foodservice environment, stainless steel equipment exists everywhere while titanium equipment is much rarer – mostly due in part to the fabrication challenges of titanium.

Winner: Stainless Steel

Cost Effectiveness

It is no surprise that stainless steel is much more affordable than titanium. Titanium is harder to machine, process & extract making it a “luxury” metal of sorts. Finished titanium food service equipment often goes for hundreds or thousands of dollars more than comparable stainless steel items.

For budget-minded, stainless steel products will fit right in the range you are expecting in terms of affordability.

Winner: Stainless Steel

Availability

As hinted above, titanium is a rare metal. Procurement & lead times can often be in excess. Stainless steel, on the other hand, is widely available in sheets, bars, rolls, tubing, etc. Stainless steel lead times are dramatically less thanks to the abundance of inventory.

If you want a specific shape or size of titanium, the lead time may also be extended due to the complex manufacturing methods involved. Stainless steel, in comparison, can be shaped easily without much of a lead time increase.

Winner: Stainless Steel

Who is the Champion?

In the world of foodservice, stainless steel is the clear winner when it comes to material choice. The big advantages of affordability, ease of use & availability are huge points to consider when meeting your project deadlines. Although titanium may end up being more durable, stainless steel durability will be more than suitable for most common kitchen tasks.

Bottom line: Although titanium does have its place in the commercial kitchen, it is stainless steel that will provide you with the biggest benefits in the short & long term.

Champion: Stainless Steel

IMC/Teddy has been working with stainless steel for almost 70 years, so we know all the ins & outs of what the metal is capable of. Type 304 stainless steel is one of the most used stainless steel alloys in today’s commercial kitchens & our preferred metal of choice. For a closer look at IMC’s products, click here.