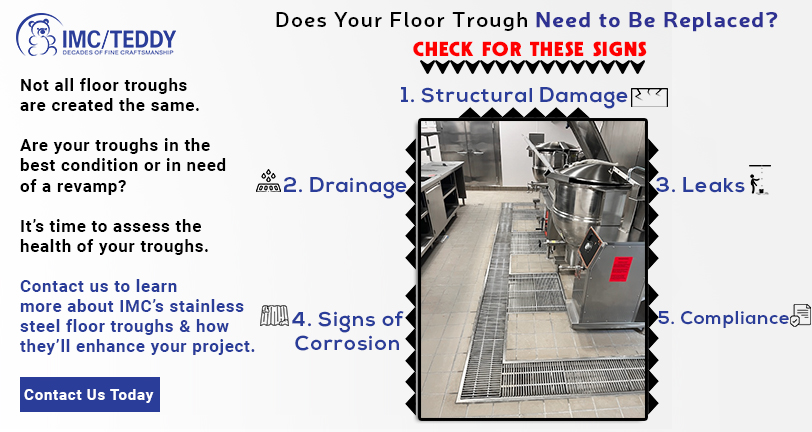

5 Signs It’s Time to Replace Your Floor Trough

Floor troughs have been around since the early 1900’s. That’s over 100 years. In that timespan, floor troughs quickly grew as one of the most effective solutions for draining excess liquids & maintaining safety. However, not all floor troughs are created the same. This is especially true for non-IMC/Teddy manufactured floor troughs where a refresh may be in order. What are the telltale signs?

In this article, we'll give you 5 signs that it is time to replace your non-IMC floor troughs. We’ll also go over some popular IMC replacements to aid in your journey. Let’s begin.

1. Structural Damage

The most important thing to look out for in a floor trough is any type of body damage. This includes cracks (big or small) or deformation. Any signs of warping or bending will compromise the drainage capacity, meaning your liquids will not be expelled quickly or at all.

Body damage is more common than you might think. With the amount of equipment & human foot traffic that floor troughs see daily, these small interactions cause heavy wear & tear over time.

2. Drainage

The drain is a vital piece of any floor trough. However, if the drain is consistently clogged, it can lead to irreparable damage. Standing water is a common indicator that a drain is not functioning in the right manner. Slow drainage is also a sign that there may be an obstruction or damage to the drain.

3. Leaks

Installing a floor trough is a science. Any miscalculation will result in loose connections which can lead to leaks. Even worse, a trough that is not properly sealed can cause water to leak into the lower floors. The result is mold & mildew problems. Try to catch any leaks as early as possible to avoid any cascading problems. Is there an easier way to prevent leakages? Yes, but more on that later.

4. Signs of Corrosion

Constant exposure to liquids can lead to corrosion. This is expedited if the floor trough is made from cheaper materials. Type 400 series stainless steel is more prone to rust due to the less nickel & chromium content. Although cheaper in price, type 400 series S/S will not hold up in the long term in terms of corrosion resistance.

Aside from that, troughs that are constantly exposed to harsh chemicals or moisture will begin to form rust. Be proactive in spotting early signs of corrosion & act upon them immediately.

5. Compliance

Building & local codes change all the time. Local codes may call for a certain number of floor troughs to be installed. Some codes may call for the floor troughs to be made of a certain material. If your current floor troughs are not up to grade, they will have to be replaced to comply with these regulations. Avoid any downtime by installing the right floor troughs.

So, What is the Replacement?

IMC/Teddy specializes in floor troughs & we’re here to provide the best trough for your application. IMC troughs come in varying lengths, widths & depths to accommodate your project. IMC floor troughs are constructed from Type 304 stainless steel, so they are of the utmost quality. As an extra add-on, seepage flanges can be optioned for your floor trough to prevent leakages to the sub floor. We stand by our quality & aim to manufacture troughs that will stand the test of time.

Aside from the troughs themselves, various stainless steel & fiberglass gratings are available to complete the package. Most IMC floor troughs are NSF certified so you are guaranteed safety & quality assurance.

For a closer look at IMC’s floor troughs, click here.