A Simple Guide on How to Maintain an IMC Can Washer

Pots, cans & utensils are being utilized in daily kitchen activities. With frequent use comes frequent washing. Can washers are specially designed to thoroughly clean & disinfect these items so they may be put back into rotation. The overall compact design paired with useful washing features makes can washers an attractive option & a powerful cleaning tool. However, can washers have many active components that will need to be regularly maintained for the best performance.

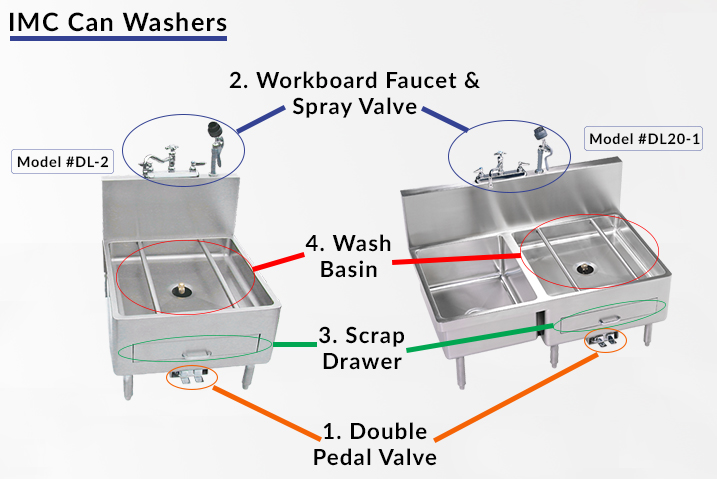

In this article, we will go over 4 ways to properly maintain your IMC can washer (Models #DL-2 & #DL20-1). We’ll also suggest some handy cleaning tools that should be used on stainless steel items in general. Let’s get started.

1. Check the Double Pedal Valve

The double pedal valve controls the high pressure nozzle spray found in the main wash basin. Without it, you would not be able to complete the entire cleaning cycle. The double pedal valve should be checked specifically for the following:

a. Ensure the hot & cold water lines are securely connected to the valve & not leaking. Make any adjustments as needed. Please note there should be (2) ½” NPT brass pipe adapters connected to the pedal knee valve.

b. Check to see if the cold water pedal is spraying cold water & the hot water pedal is spraying hot water. If not, there is a plumbing issue.

c. Periodically test the foot pedals for operation. If no water is spraying when a pedal is hit, there may be an issue with the valve assembly itself. Check for any visible signs of damage to the assembly.

2. Inspect the Workboard Faucet & Spray Valve

Moving toward the top of the can washer, you will see a workboard faucet & a spray valve with brush. The faucet is used for pot filling & cleaning. The spray valve helps to loosen solid waste from objects. Make sure all plumbing is tight & secure with no leaks. Make sure the handles on the faucet are operating & the spray valve is operarting correctly. All IMC can washers have open backs so access to plumbing should be no problem.

3. Empty Your Scrap Tray

Through the cleaning cycle, loosened debris will fall into a perforated scrap drawer located underneath the main wash basin. This drawer can accumulate solid waste quickly & should be periodically emptied to avoid clogging. Simply slide out the drawer, empty it, rinse it off & insert it back into the can washer as before. Do not operate your can washer without the scrap drawer!

Another useful tip – never leave excess waste or stalled water treated with chemicals in sink/scrap drawer for a prolonged period of time as it may cause pin holes to the metal.

4. Sanitize Your Wash Basin

After each cleaning cycle, be sure to clean out scrap drawer & wipe down the main wash basin with a stainless steel friendly cleaner. Keep away from abrasive cleaners that contain chemicals such as fluorine or chlorine. Use simple cleaning agents such as vinegar, baking soda, turpentine or alcohol to keep your can washer fresh.

Model #DL20-1 has an additional utility sink for holding & drying washed utensils. Be sure to clean & sanitize this sink as well.

Can washers provide endless value for sanitizing medium sized pots & utensils. Overall, IMC can washers can improve your overall operational efficiency & reduce costs associated with cleaning & sanitation. For DL-2 maintenance tips , click here. For DL20-1 maintenance tips, click here.