Equipment Stands: The Complete FAQ

Equipment stands are an offshoot of the standard worktable found in the IMC catalog. They have some noticeable differences that give them an entirely different purpose in a commercial environment. Do you know the ins & outs of equipment stands? Let’s answer some common questions.

In this article, we'll go over the most asked questions about equipment stands & give you some advice on applications as well. Let’s begin the Q&A.

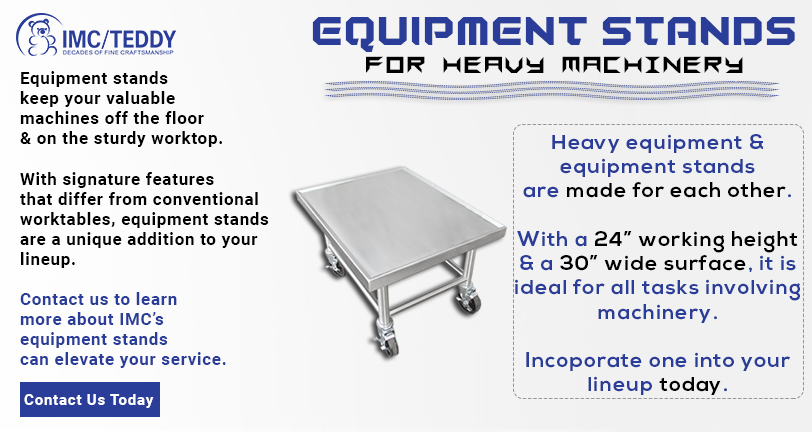

1. How Are Equipment Stands Different from Worktables?

Let’s begin with the basics. Worktables are primarily used for prep tasks with some storage. Equipment stands do not actually follow this principle. This is because equipment stands are designed to house heavy machinery (such as slicers, charbroilers, burners, kettles, etc.) atop of them. How?

Equipment stands have a working height of 24” rather than the standard 34” found on other IMC worktables. In order to operate this machinery comfortably, the height of the stand is lowered.

Equipment stands also feature a 30” wide surface with anti-slip/spill edges with turn ups on the sides & rear as a standard so heavy machinery will not slide off the surface. This is particularly useful if you are dealing with dangerous equipment such as slicers or fryers.

Lastly, equipment stands are always lower gauge & feature reinforced channeling to be able to accommodate even the heaviest machinery.

2. Any Weight Limits?

We recommend no more than 750 lbs. shall be placed on top of any IMC equipment stand. If you notice sagging or buckling on the surface, refrain from stacking any larger items.

3. Are They Mobile?

Standard IMC equipment stands come with stainless steel legs with adjustable bullet feet. A common option would be to outfit your equipment stand with casters so it can be maneuvered around your facility with ease.

4. I’m Dealing with a lot of Debris/Scraps, How Do Equipment Stands Solve This Problem?

In eateries such as bakeries or pizzerias, crumbs are a common occurrence when using machinery.

IMC came up with a way to solve this by creating Model #ESTP, which features a perforated surface & a scrap tray to capture all the waste. The scrap tray can then be removed, cleaned off & reinserted back into the stand during working hours.

Equipment stands are engineered for heavy use & years of service in high volume commercial facilities. They are useful for most foodservice lineups & a must have if you continually work with heavy machinery. For a closer look at our equipment stands, click here.