Everything You Wanted to Know About Stainless Steel Gauges

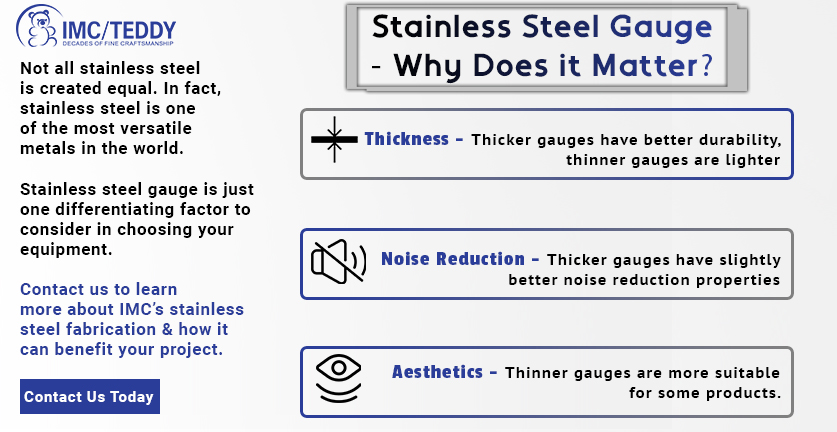

Stainless steel might all look at the same on the surface, but there are many differences. One major difference is the stainless steel gauge (or thickness). But, why exactly does stainless steel have varying degrees of thickness? We’re here to fully explain.

In this article, we’ll break down the characteristics & uses of the most common stainless steel gauges used in food service equipment. We’ll then briefly display the gauges for select IMC products. Let’s start.

Stainless Steel Gauge Breakdown

Let’s begin simple – the most common types of gauges used in food service equipment are 12, 14, 16, 18 & 20. The higher the gauge, the thinner the metal. Here’s what each gauge actually means:

12GA – Measures 0.109375 inches or 7/64th of an inch thick. It’s the thickest (& heaviest) stainless steel gauge suited for items that will see major abuse throughout its lifespan. It is also the most expensive of the gauges. Sound deadening is also the best here because of the thicker structure.

14GA – Measures 0.078125 inches or 5/64th of an inch thick. It’s the most popular gauge for food service equipment – perfect for products that will see heavy abuse throughout their life cycle. This gauge is considered “heavy duty.”

16GA – Measures 0.0625 inches or 1/16th of an inch thick. It’s also considered a commonly used gauge in food service equipment for its right balance of durability & cost effectiveness. This gauge is considered “standard duty.”

18GA – Measures 0.05 inches or 1/20th of an inch thick. The thinner design is useful for items that won’t see much movement such as shelves or cabinets. This gauge is considered “light duty.”

20GA – Measures 0.0375 inches or 3/80th of an inch thick. It’s the thinnest (& lightest) stainless steel material, but it’s trending downward in popularity. It is great for light duty hand sinks, trim pieces & wall flashing.

Which Gauge is The Best?

Now that you have an idea about stainless steel gauges, the question of which one is “the best” comes into play. The truth is not one gauge is superior over another. It will depend on the environment you plan to use your equipment. Busier areas will want to opt for a thicker gauge, while quieter areas will do fine with a thinner gauge.

IMC Product Gauges

IMC/Teddy manufactures all products using Type 304 Stainless Steel with differing gauges based on product. While most of these products can have the gauge adjusted as an option, here are the standard gauges for major IMC items:

IMC/Teddy understands that the gauge & type of your stainless steel products plays into the longevity of your equipment. Armed with this knowledge, we are fully committed to bringing you a complete lineup of stainless steel foodservice equipment that works for you. To learn more about how IMC can cater to your stainless steel needs, click here.