A Simple Guide on How to Maintain Stainless Steel Shelving

Shelving has become an increasingly popular piece of equipment in today’s commercial environment. This comes as no surprise as it fulfills many tasks: storage, organization & transportation. Shelving is also used daily in commercial environments. As with any other piece of equipment, the more you use it – the more you must maintain it. Shelving fits this description (and more).

In this article, we will go over 4 ways to properly maintain your IMC shelving unit. We’ll also suggest some handy cleaning tools that should be used on stainless steel items in general. Let’s begin.

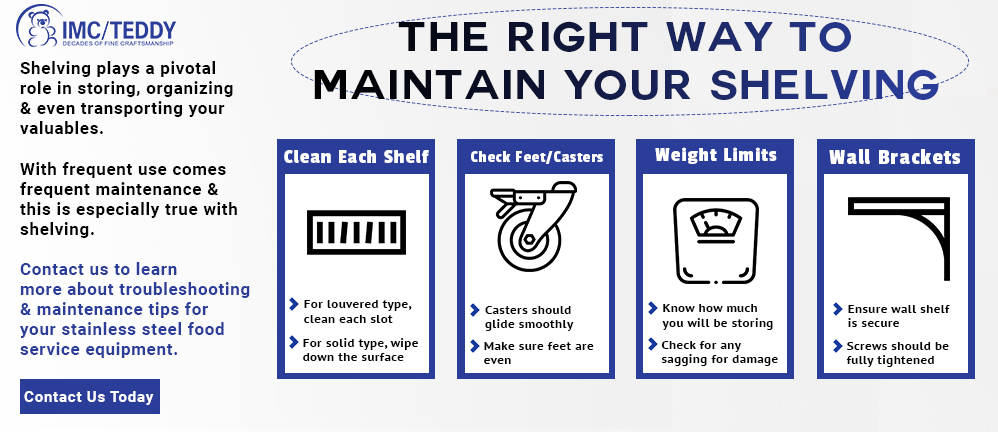

1. Clean Each Individual Shelf

Dirt, grease & debris can add up quickly when using your shelving system. The first order of business is to clean & sanitize each individual shelf (or tier) of your system. This means thoroughly going over each crevice & not missing anything. Yes, that means cleaning underneath each shelf also.

For louvered type shelving, this can be a tough task as each slot will need to be attended to. For solid type shelving, it’s a quick, smooth wipe down. Always remember to use a mild solution like rubbing alcohol or baking soda (do not use anything that contains chlorine) and no abrasive tools (no wool or wire pads). Here is some more general stainless steel cleaning tips to guide you along.

2. Check the Feet or Casters (if Equipped)

Each IMC shelving unit comes with stainless steel adjustable feet. Make sure each foot is level & firmly planted on the ground. An uneven shelving system could mean a tip-over & potential injury or death. Check to see that nothing is underneath the feet also.

If your shelving system is equipped with casters, inspect each wheel for any damage. The wheels should not be dragging along the floor when in motion – everything should be a smooth glide. Test out the brakes periodically for function.

3. Respect the Weight Limits

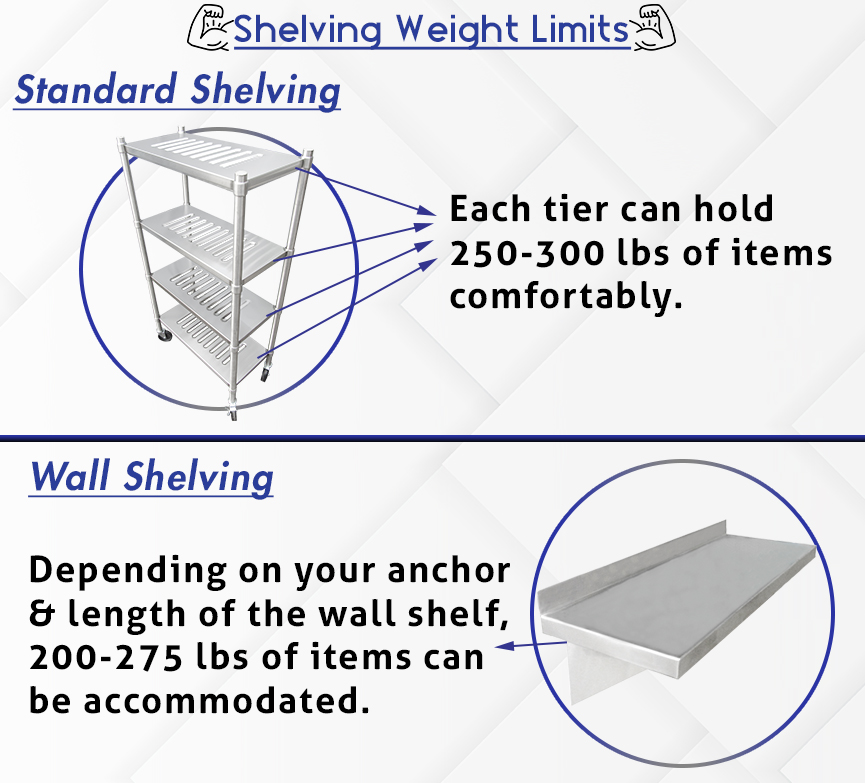

Although more of a preventative maintenance tip, knowing the total weight of the items you plan on storing is key.

In fact, one of the most frequent questions we get is: “How much is too much?” Overloading a shelf can lead to sagging & in extreme cases, permanent damage. It’s important to take note of the weight of the items you are putting on your shelf & avoid stacking if possible. Here is a handy graphic to remember when using your equipment:

4. For Wall Shelving – Be Mindful of the Wall Brackets

This goes along with the weight issue mentioned above. Check the status of the wall brackets on your wall shelving. Make sure they are 100% secure to the wall with no wobbling & shakiness. One of the worst scenarios to happen is having a wall shelf falling down because of overloading.

Mounting your wall shelf properly to the wall takes no more than a power drill & a few screws. Also check to see that the shelf is perfectly straight so items can stay in place when stored.

IMC/Teddy manufactures a wide variety of shelving systems, all made from Type 300 Series Stainless Steel. Keeping up with the maintenance is the best way of prolonging the life of each of your shelving systems. For our full shelving lineup, click here.