Why Type 300 Series Stainless Steel is the King of Food Service

Stainless steel equipment has been the foundation of the food service industry since the early 1900’s. This is not surprising since stainless steel is considered of the most versatile & hygienic metals in the world. However, just as with most metals, there are several different variations that can change its uses in the real world. Stainless steel is no exception.

In this article, we will break down why type 300 series stainless steel is the dominant force in the food service industry & compare it with other types of stainless steel out today. Let’s jump right in.

Type 300 Series Stainless Steel – The Definition

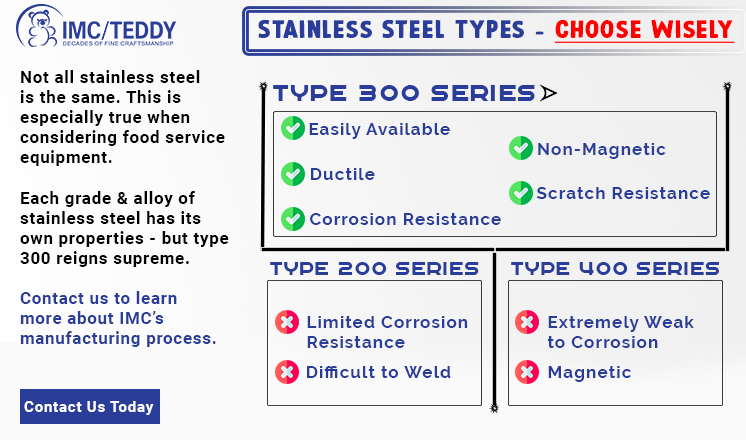

So, what exactly is “Type 300 Series” stainless steel? Here are the main features & advantages to keep in mind (without getting too scientific!):

- It’s one of the most common steels available, so it can be acquired easily.

- Extremely Ductile – meaning it can be formed into a variety of different shapes to fit most applications.

- Corrosion Resistance – the best of any stainless steel grade. Able to withstand acids, alkalis & chlorides (such as salt).

- Non-Magnetic (austenitic) – good for food service applications since appliances/tools will not stick to the surface.

- Scratch Resistance – stands up to the common wear & tear.

Type 300 Series stainless steel can be broken down into different alloys such as 304, 316, 302, 303 & so on. 304 & 316 are the most common alloys for food service equipment. 316 has a better resistance to chemicals/chlorides, but 304 is relatively cost effective.

What about Type 200 & Type 400?

It is true that type 200 & type 400 are used in the food service industry. However both types have glaring flaws:

Type 200 Series Stainless Steel

- Corrosion Resistance is limited. This means it is a less hygienic metal & in the food service environment that is unacceptable. The food service industry is extremely strict when it comes to compliance & adhering to regulations. Employing metals that pose a contaminant risk will not pass any regulations.

- Welding is tremendously difficult, especially to thicker surfaces – almost to the point where cracking is a known, major issue. This can pose a problem when working with equipment dealing with water or other liquids.

Type 400 Series Stainless Steel

- It lacks nickel in its composition so; once again, corrosion resistance is weak when compared to Type 300.

- Magnetic properties (ferritic) – Type 400 Series stainless steel is magnetic so metal-to-metal contact should be monitored. As mentioned above, metal appliances/tools (such as knives) WILL stick to the surface.

IMC’s Stainless Steel Grade of Choice

IMC/Teddy uses only type 300 series stainless steel – in particular the 304 & 316 alloys. We believe the balance of performance & versatility far outweighs the other types of stainless steel. It is the most accepted metal in the industry today & brings endless amounts of benefits to the end user.

IMC/Teddy starts construction of each stainless steel item from a flat sheet of Type 300 Series stainless steel & continues the process all the way to shipping. With many products NSF approved, IMC is committed to manufacturing the highest quality items in the food service industry. To learn more about how IMC can cater to your stainless steel needs, click here.