IMC/Teddy – Minimal Assembly Required

Let’s face it – assembling a product, especially one you’re not familiar with, can be a crippling state of affairs. Picture this situation – you place an order for a couple of dispensers. You have a tight deadline & minimal staff to work with. The products finally arrive on the project site, but you realize that they need some complex assembly in order to function properly. On top of that, you are required to purchase some other accessories in order to operate the products correctly.

Luckily, most IMC/Teddy products do not have this issue at all.

In this article, we’ll break down some examples of how IMC/Teddy products ship with close to no loose items & why this is important in the grand scheme of things. Let’s begin.

Keep It Together

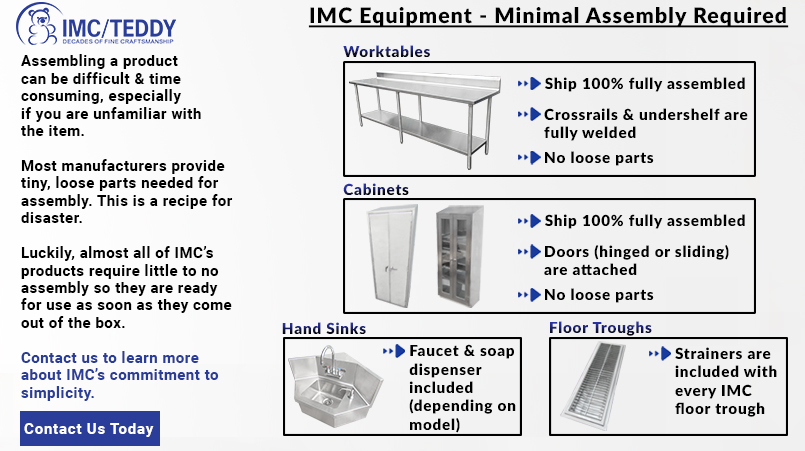

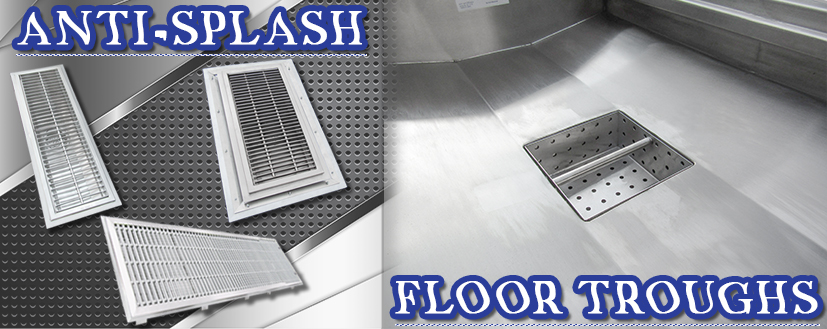

IMC/Teddy products put function at the forefront of every product design. This means keeping the loose parts to a minimum so setup & operation can be seamless. For example, a strainer on a floor trough is an essential, but often forgotten piece. Every IMC floor trough comes with the appropriate strainer.

Faucet & soap dispensers for hand sinks are vital & come standard with each IMC unit. IMC mop sink cabinets come with the appropriate faucet and/or hose to operate the unit easily. Everything you need to get your equipment up & running comes with each product. No other extra major components are needed.

A prime example of how we keep our equipment together are our worktables. Most manufacturers ship worktables to you knocked down, so putting them together is a must. IMC ships worktables to you completely assembled so no loose items are present. All you have to do is set up the worktable in your desired spot & the unit is ready for use.

Another example of this are IMC cabinets. IMC cabinets ship fully assembled with the appropriate doors already installed onto the cabinet body. No complicated assembly is needed to start using your cabinet. Other manufacturers ship the doors loose, so having your cabinet come together perfectly can be a challenge.

So, Why Does It Matter?

As mentioned in the opening, time is of the essence. No one wants to spend countless hours on getting equipment to function when that time can be used to complete other aspects of the project. Having equipment that requires minimal installation cuts down on time lost & increases your productivity substantially.

Also, having too many loose items shipped with your main equipment can present the problem of misplacement & theft. Loose items can end up in the wrong area of the site easily without anyone’s knowledge. This will lead to potentially ordering expensive replacements.

IMC/Teddy understands that your time is important & projects can have tight deadlines. Having as little loose parts as possible is just one way to save you time & focus on other activities. To learn more about how IMC can cater to your stainless steel needs, click here.