IMC/Teddy: Pioneers of Stainless Steel Worktables

Worktables may seem like a common & simple item in a commercial facility, but are you getting the most out of them? The truth of the matter is your worktables should be doing more for you. Here’s where IMC comes into play.

We’d like to take a deep dive below into some of our worktable offerings & give you some advantages of utilizing an IMC worktable for your project. Let’s begin.

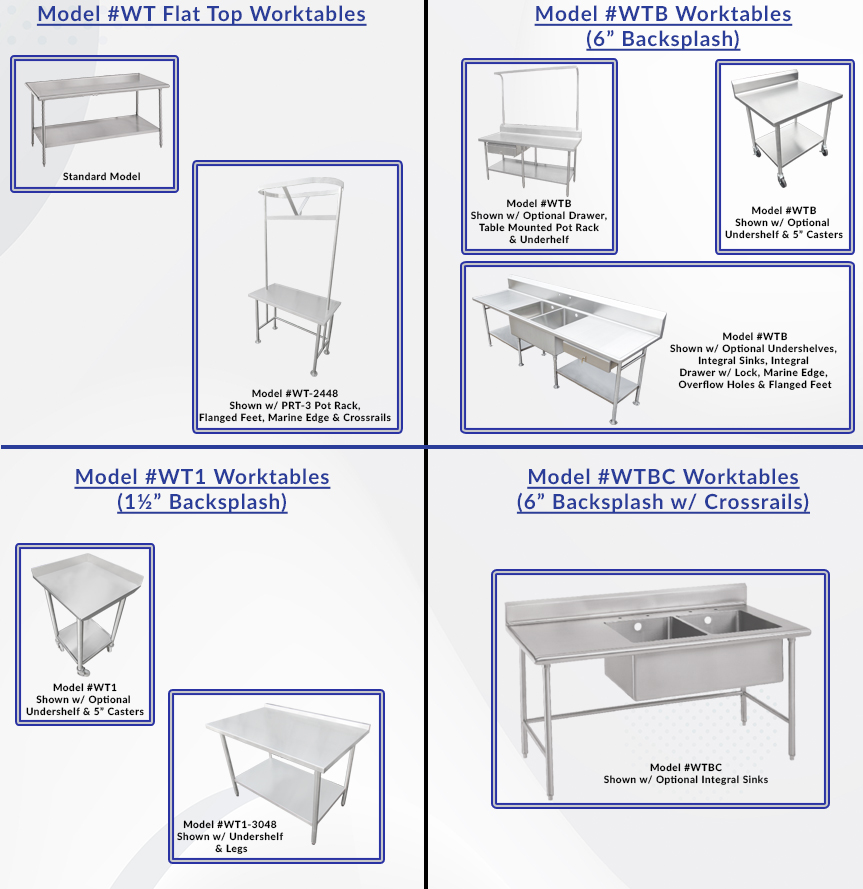

Worktables (Model #WT Series)

Model #WT is useful for performing all of your prep tasks & laying your items on. The unit can be 14 or 16-gauge depending on your application. Every part of the worktable is made of stainless steel; you will not find any galvanized or plastic parts in our design.

Model #WTB is the same as above except it has the addition of a 6″ high backsplash to protect your walls from damage. Model #WT1 features a 1½” backsplash & Model #WTBC includes a 6″ backsplash & crossrails for stability.

Of course, options are selectable for your worktable. Some common options include flanged feet, rolled edge, marine edge & removable undershelf among others. Here’s a look at the various models:

Mixer & Slicer Tables

IMC mixer & slicer tables are specially designed to hold your bulky mixers, blenders, slicers, etc. during service hours. In essence, they free up other worktable space & provide a mobile way of moving your equipment around the facility. Each table is constructed features a 14-gauge stainless steel top & an 18-gauge undershelf. 5″ casters are standard.

IMC offers up 4 different mixer/slicer tables:

1. Model #SMT – The standard mixer table comes equipped with an undershelf to meet your storage needs.

2. Model #SMTS – It’s the same form as the SMT but with added 14-gauge welded tray slides so you can carry all of your trays around the facility.

3. Model #SMTT – This unit features a unique fully welded 56″ high tool tree allowing you to hang your small tools & appliances.

4. Model #SMS/SMSS – The unit has optional adjustable pan slides. The bottom has a sanitary marine edge at front & is supported on heavy duty stainless steel adjustable legs.

Here’s a quick glance at all four models below:

Equipment Stands

For that unwieldy equipment such as griddles & charbroilers, you’ll need specialized worktables to accommodate these heavy items. Equipment stands are the best choice for this. Standard Model #EST is constructed from 14-gauge stainless steel with an 18-gauge undershelf. The understructure is rigidly braced so it is able to hold the heaviest of equipment.

Introduced in 2019, Model #ESTP is the next evolution of the equipment stand. It’s outfitted with a perforated top & a slide out tray so you can clean up any loose scraps. Recommended for equipment where crumbs & waste are commonplace such as bread slicers & dough dividers.

IMC also offers angle frame scale stands (Model #STS) to provide a perfect place to set your scale on. The unit includes casters so you can easily maneuver your scale around the facility. Crossbracing is also standard for the best possible rigidity. Custom sizes are available to fit your specific scale model #.

Take a look at IMC’s equipment stands below:

Misc. Worktables

IMC also offers other worktables to fit a specific application. Model #FWT filler worktables are designed to expand capacity & increase your production. Most importantly, they fill those awkward gaps. Filler worktables not only provide additional prep space, they also offer further storage locations for equipment.

Mobile bowl stands are beneficial for tasks needing the use of a mixer bowl. These tasks include mixing batters, blending soups, marinating meats & so on. Typical units can accommodate either a 30-quart or 80-quart bowl size. As always, custom sizes are available.

What’s the Real IMC Advantage?

You just received the crash course in IMC worktables, so why choose them for your next project?

1. Design Philosophy – Competitors are using 18, 16 & 14-gauge type 400 series stainless steel when constructing their worktables. Type 400 series stainless steel may be cheaper, but it is not as durable & unsanitary in food service industry applications. IMC is using 14 & 16-gauge type 300 series stainless steel only. There is no substitute for quality.

2. Stainless Steel vs. Galvanized Steel – Many competitors cut corners by providing lower quality galvanized steel instead of the better stainless steel. Competitors are using a galvanized undershelf while IMC is using an 18-gauge type 300 series stainless steel undershelf.

3. Gussets & Bullet Feet – Competitors will use plastic gussets & bullet feet. Plastic parts will never stand up to the long term wear & tear. On top of that, competitors will use cheaper galvanized legs. IMC uses stainless steel gussets, bullet feet & legs on each worktable produced in our factory.

IMC/Teddy stainless steel worktables are engineered for heavy use & years of service. We are confident that adding these worktables to your existing lineup will boost your overall efficiency & throughput.