Wall Flashing – The Complete FAQ

Think about the engineering & planning that goes into constructing a building. The materials, layout & architectural styles are just some factors that fit into the bigger picture. It can take months, even years, to fully construct a facility & there can be unforeseen issues that pop up along the way. One of those issues may be the problem of outside water leaking in. How can this be prevented?

In this article, we'll go over 4 common questions about wall flashing including what it is, its purpose & styles. Let's jump right into question #1.

1. What is the Point of Wall Flashing?

Let’s start with the basics.

Wall flashing prevents water from rain or snow from entering the building. The main idea is that flashing prevents water damage that can eventually lead to rot or mold. Wall flashing is critical to your building’s health & can save you from future headaches when installed properly.

Wall flashing collects all the moisture & redirects it to a gutter or drainage system. The key is to place wall flashing in areas where water intrusion can be a problem. Once this is in place, wall flashing can prove to be an invaluable tool.

2. What is Wall Flashing Made Out of?

The most common materials are aluminum, copper & stainless steel. Let’s break down all three materials:

Aluminum – although lightweight & cheaper, aluminum offers lower durability & can react with other materials negatively in the area.

Copper – can be aesthetically pleasing, but it is susceptible to corrosion when exposed to high water flow. It also suffers from the same reactivity problem as aluminum when it encounters other materials.

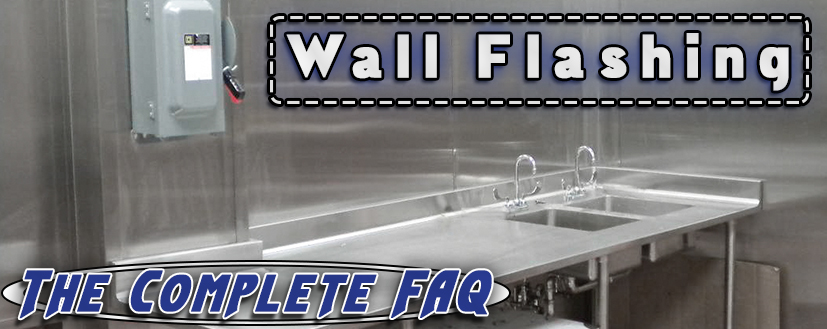

Stainless Steel – it is a higher cost option, but stainless steel offers the best durability & longevity. It also offers the best corrosion resistance, so it is a perfect fit for areas where high moisture is expected.

3. Where are the Best Areas to Install Wall Flashing?

The answer will vary from building to building, but here are some of the important spots to pay attention to:

– At the intersection of where the roof & wall meet (this means both endwalls & sidewalls)

– Common roof penetrations such as vents or skylights. Chimneys are also a hot spot.

– By windows & doors

– Base of walls

– Cook Areas & Dishrooms

To sum up, any points of structural support need to be focused on. Try to survey your building & assess where potential leaks may occur & act from there.

4. How Much Do I Need & How Do I Order Flashing?

Speaking for IMC stainless steel wall flashing – it can be constructed from 18- or 20-gauge Type 304 stainless steel with a standard width of 48”. Heights can range from 84” – 120”. These numbers can be customized to fit your application, of course. Divider strips are also included for your convenience.

The amount you need will highly depend on your building layout. Remember it is better to have plenty of wall flashing on hand in case any emergencies pop up that may have been overlooked.

IMC offers Model #WFT wall flashing for your moisture prevention needs. IMC understands the risk & cost of water leakages, especially in a busy commercial environment. With wall flashing, this potential hazard is eliminated. To learn more about wall flashing in general, click here.