Most Common Mistakes When Cleaning Stainless Steel

Let’s face it – cleaning can be a tedious, unending task. In the commercial environment, especially kitchens, it is a necessity that cannot be ignored. Stainless steel equipment is no exception. Cleaning stainless steel maintains its aesthetic, and keeps surfaces sanitary for food related tasks. However, mistakes can tarnish your stainless steel leading to a short lifespan & eventual costly replacements. We’re here to provide the most up-to-date cleaning tips.

In this article, we’ll detail out the 5 most common mistakes when cleaning stainless steel equipment & offer up solutions as well. Let’s jump right into #1.

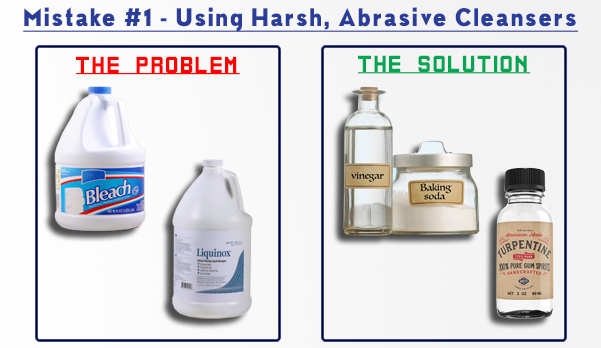

Mistake #1 – Using Harsh, Abrasive Cleansers

The Problem: Abrasive cleansers that include bleach or chlorine are effective for removing stains, fingerprints & other dirt. However, it will absolutely ruin the finish of your stainless steel. Using these cleansers over time will permanently dull & ultimately tarnish the surface of your stainless steel. Scouring powders, plain ammonia & oven cleansers are also giant offenders.

The Solution: Use a gentle cleanser such as baking soda, vinegar, turpentine or alcohol. Any non-gritty abrasive is perfectly acceptable. Just be sure to check the label of each cleanser & make sure it does not contain bleach or chlorine.

Mistake #2 – Using Coarse, Rough Tools

The Problem: Steel wool pads, steel brushes or any wire products are unhealthy for stainless steel. Steel wool pads can break apart & cause small particles to become embedded on the surface of the product. Eventually these particles will rust & discoloring will occur. Not to mention, these products cause massive scratches on the metal surface.

The Solution: Go soft. In fact, all you really need is a damp cloth. But if you really want to take it to the next level, invest in a microfiber cloth. These cloths are pliable & will produce much better results in the long term.

Mistake #3 – Not Wiping with the Grain

The Problem: Dirt, grime & dust becomes trapped on the surface of stainless steel every minute. These particles become trapped in the minuscule grooves of the steel. Not wiping with the grain means you are missing these microscopic particles.

The Solution: Take a look at your stainless steel equipment. You’ll notice almost a “line” shaped pattern on the surface. If the pattern faces vertically, wipe vertical. If the pattern faces horizontally, wipe horizontal. Here’s a helpful visual:

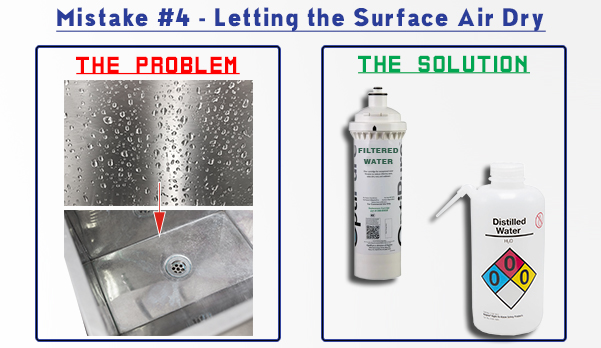

Mistake #4 – Letting the Surface Air Dry

The Problem: Tap water is “hard” – meaning it is rich in minerals & can leave behind white spots when left to air dry. Stainless steel is susceptible to hard water staining so that means forgetting to wipe down areas of your equipment can tarnish the surface.

The Solution: If you only have tap water available, always remember to wipe down every crevice of your product thoroughly. An even better solution is to invest in distilled or filtered water where staining is diminished. No matter what solution you pick, stainless steel equipment should be dry to the touch when you are finished. Rinsing & drying is key!

Mistake #5 – Not Cleaning Often Enough

The Problem: Infrequent cleaning can lead to health hazards & potential damage to your stainless steel equipment. The risk of discoloring & tarnishing becomes a real issue. Cleaning once per week is just not enough.

The Solution: Clean daily. Make it a routine to clean (with the correct washing products) everyday. This will boost hygiene & promote a healthy environment for patrons & employees. Most of all, your equipment will look shiny & new.

Stainless steel equipment requires constant maintenance & attention. Following the above tips will only prolong the life of your equipment. For more IMC maintenance tips, click here.