Why You Should NEVER Deep Draw Sink Bowls

Sink bowls are the heart & soul of any common hand/utility sink. It’s the sink bowl’s job to collect excess water & drain it quickly. With that said, they are in constant use & see action on a frequent basis. You’ll want a sink bowl that will stand the test of time. Do deep drawn sink bowls meet the criteria? Well…

In this article, we'll go over 3 reasons to avoid deep drawn sink bowls & explain the alternative. Let's talk about it.

But First…

Let’s define “deep drawn.”

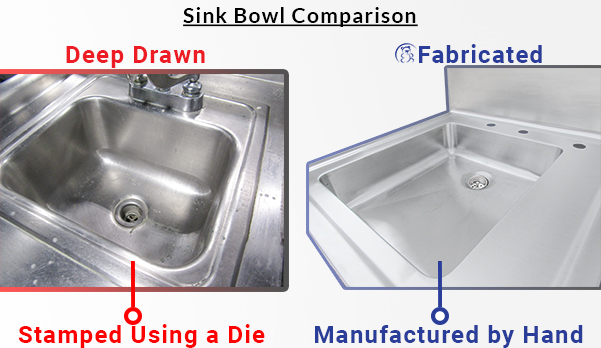

Deep drawing is the process of using a high-pressure stamp (or “die”) to form shapes out of a flat stainless steel sheet. The process takes only seconds & minimizes labor involved. Extra welding is also eliminated so quicker turnaround is the biggest advantage. It’s a common way of creating sink bowls that has, unfortunately, become commonplace.

A. Durability Concerns

The biggest problem with deep drawn sink bowls is the durability factor.

During the deep drawing process, the durability of the metal is compromised. In a sink bowl’s case, the bottom portion of the bowl is thinned out. This will lead to holes forming at the corners, so cracks will become evident eventually.

On top of this, deep drawing compromises the gauge of the metal because of the intense stretching. One section of your finished product might be 14-gauge while the stamped-out portion might be a thinner 16- or 18- gauge.

B. Corrosion Risk

Stainless steel, in particular, has a protective layer called chromium oxide, which naturally resists corrosion of the metal. This thin layer is stripped away during the deep drawing process; thus, corrosion is a real potential issue. In the world of sink bowls, this leads to unsanitary conditions that will not meet any building or local codes.

Overall, corrosion severely diminishes the lifespan of a product, so costly replacements will be needed.

C. Size Restrictions

The dies used in the deep drawing process are a specific size, so custom shaped sink bowls are out of the question. Contrast this with fabricated sink bowls where the bowls are welded together & can be custom shaped with a varying depth as well.

So, What’s the Alternative?

The answer is simple – standard fabrication. IMC’s manufacturing process for sink bowls involves lasering out the shape of the bowl from a flat stainless steel sheet, bending the sides into a bowl shape, welding the sides together then polishing the entire sink bowl for a clean look. There are many big advantages to this:

1. Gauge Uniformity– This means durability will remain intact because no intense pressure is put on the metal during manufacturing. You will not lose metal thickness.

2. 100% Sanitary – The chromium oxide layer is not harmed during the fabrication process, so the final product remains hygienic.

3. Custom Shapes/Sizes – Fabrication allows IMC to meet your demands for shapes & sizes due to the flexible components involved.

Here’s a visual comparison:

With the above mapped out, it’s clear that deep drawing sink bowls is not the best option for your project. Rely on fabrication to bring you a product that will meet your demands & expectations. For a closer look at our sink bowl fabrication, click here.